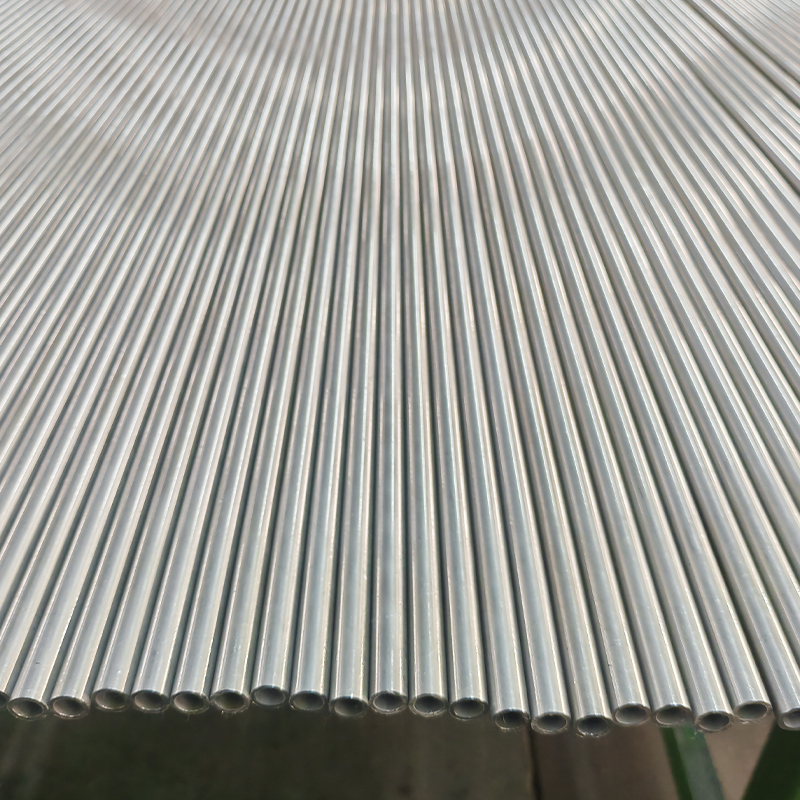

Dimensional Accuracy and Its Impact on Hydraulic System Stability

In hydraulic systems, dimensional accuracy of cold-drawn seamless hydraulic tubing directly influences sealing performance, pressure stability, and long-term reliability. Tight OD and ID tolerances help maintain consistent wall thickness, which reduces localized stress concentration under high-pressure cycles. For applications such as construction machinery and industrial hydraulics, stable dimensions allow precise matching with fittings, valves, and connectors, minimizing leakage risks and assembly deviations.

Manufacturing processes that combine cold drawing with online dimensional monitoring enable real-time control of tube geometry. This approach supports stable batch-to-batch consistency, which is particularly important for global OEMs that require interchangeable components across different production lines.

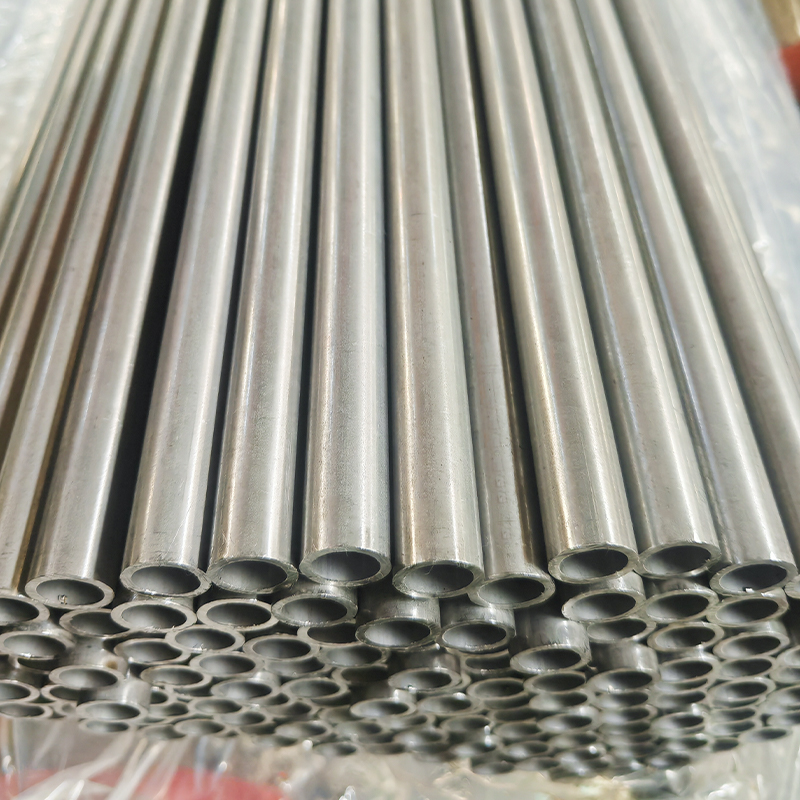

Cold Drawing Effects on Mechanical Properties

Cold drawing refines the grain structure of seamless hydraulic tubing, resulting in improved tensile strength and surface integrity. Compared with hot-finished tubes, cold-drawn tubing shows reduced surface roughness and enhanced straightness, both of which contribute to smoother fluid flow and lower pressure loss in hydraulic circuits.

Strength Uniformity After Heat Treatment

Post-drawing heat treatment balances strength and ductility by relieving internal stress introduced during deformation. This step is critical for tubing used in dynamic load environments such as automotive chassis hydraulics, wind energy pitch control systems, and railway braking systems. Controlled heat treatment ensures predictable mechanical behavior during bending, flaring, and long-term service.

Surface Quality and Internal Cleanliness Requirements

Internal surface quality of cold-drawn seamless hydraulic tubing plays a key role in extending the service life of pumps, cylinders, and valves. Smooth inner walls reduce friction and limit particle adhesion, which helps maintain hydraulic fluid cleanliness over extended operating periods.

- Lower internal roughness supports stable flow and pressure response

- Improved cleanliness reduces wear on precision hydraulic components

- Consistent finishing simplifies downstream flushing and assembly processes

Application-Oriented Tubing Selection Across Industries

Different industries impose distinct performance expectations on cold-drawn seamless hydraulic tubing. Selection often depends on operating pressure, environmental exposure, and system layout. Manufacturing flexibility, including small-batch customization, supports diverse application scenarios without compromising quality consistency.

| Industry Sector |

Key Tubing Focus |

| Construction Machinery |

High pressure resistance and fatigue performance |

| Automotive Systems |

Dimensional consistency and formability |

| Wind Energy |

Long-term stability under cyclic loads |

| Oil and Gas |

Material integrity and surface protection |

Quality Control Practices in Hydraulic Tubing Manufacturing

Consistent quality in cold-drawn seamless hydraulic tubing relies on integrated inspection throughout the production process. Non-destructive testing methods such as eddy current and ultrasonic inspection help detect surface and internal defects without compromising tube integrity. Chemical analysis ensures material composition remains within specified ranges for mechanical and corrosion-related performance.

Online monitoring systems further enhance reliability by tracking dimensional changes during production. Combined with automated straightening, cutting, chamfering, and surface treatment, these controls support stable output suited for high-mix, low-volume industrial demands.

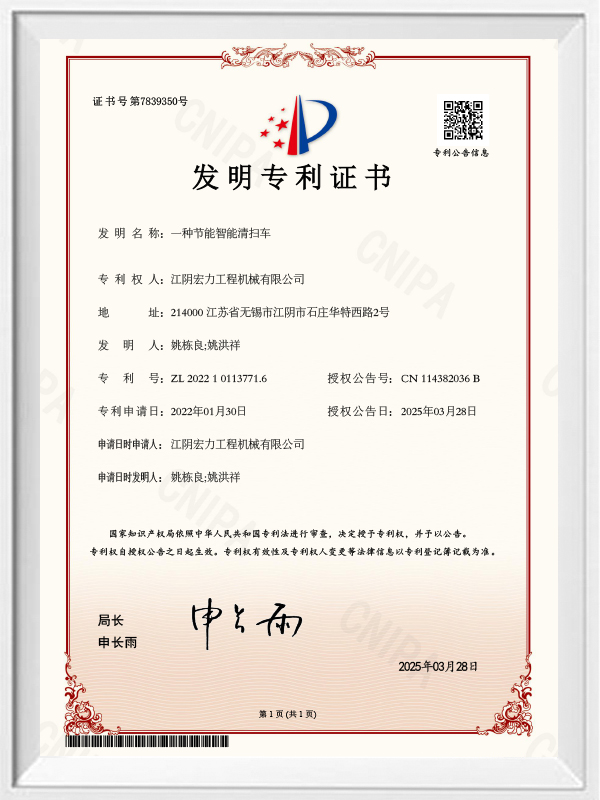

Manufacturing Flexibility and Long-Term Supply Value

For global hydraulic system manufacturers, long-term supply stability is closely linked to a supplier’s manufacturing flexibility and process integration. Facilities that combine R&D, production, inspection, and finishing within a unified system can respond efficiently to specification changes, customized tolerances, and evolving industry standards.

Continuous investment in automation and smart manufacturing enables consistent delivery of cold-drawn seamless hydraulic tubing while supporting sustainability and compliance with international certifications such as ISO 9001, ISO 14001, CE, and RoHS.

English

English Español

Español русский

русский