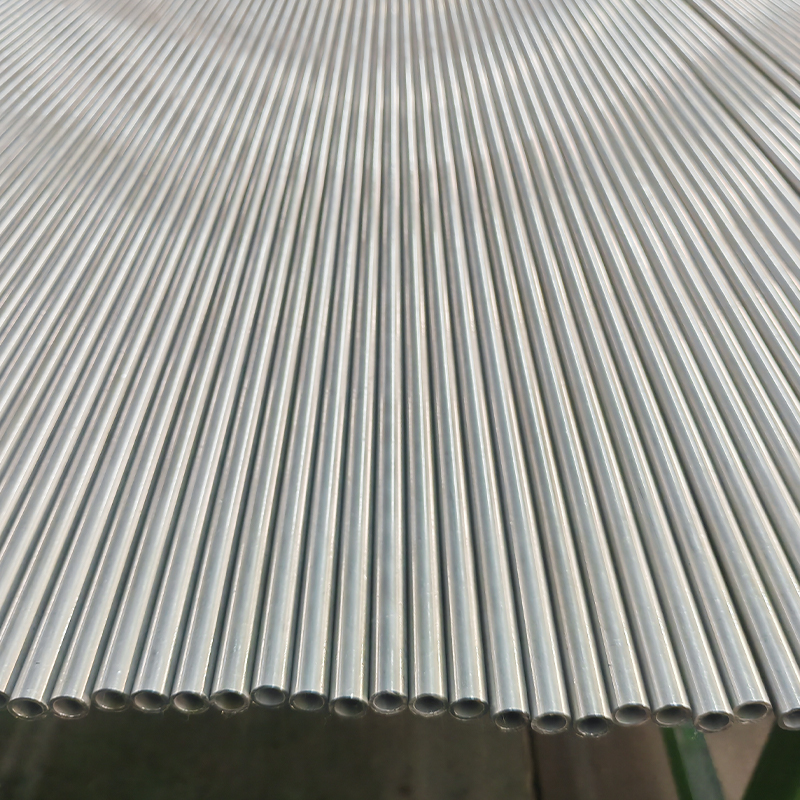

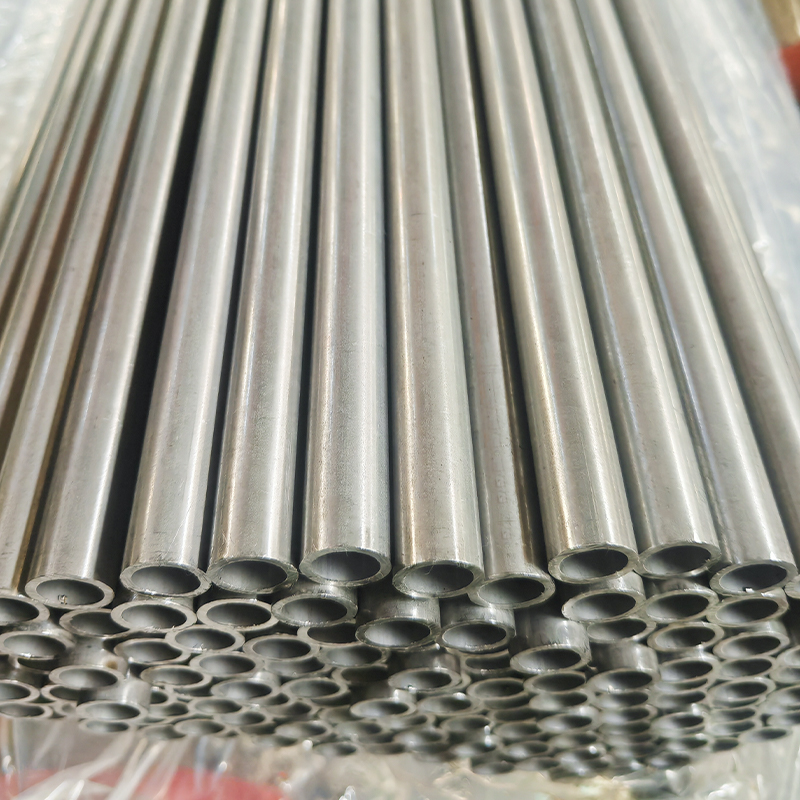

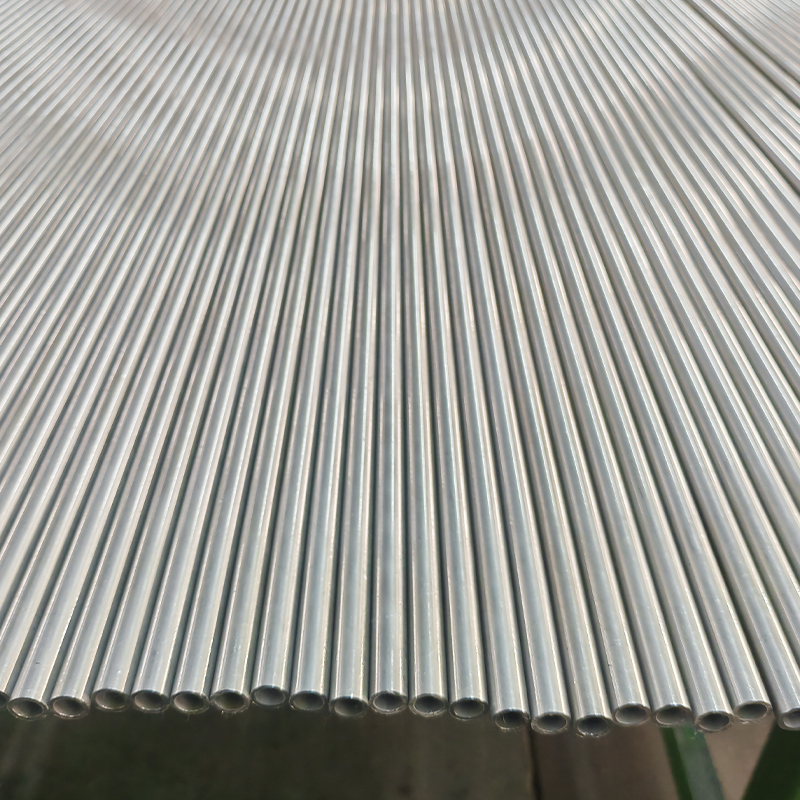

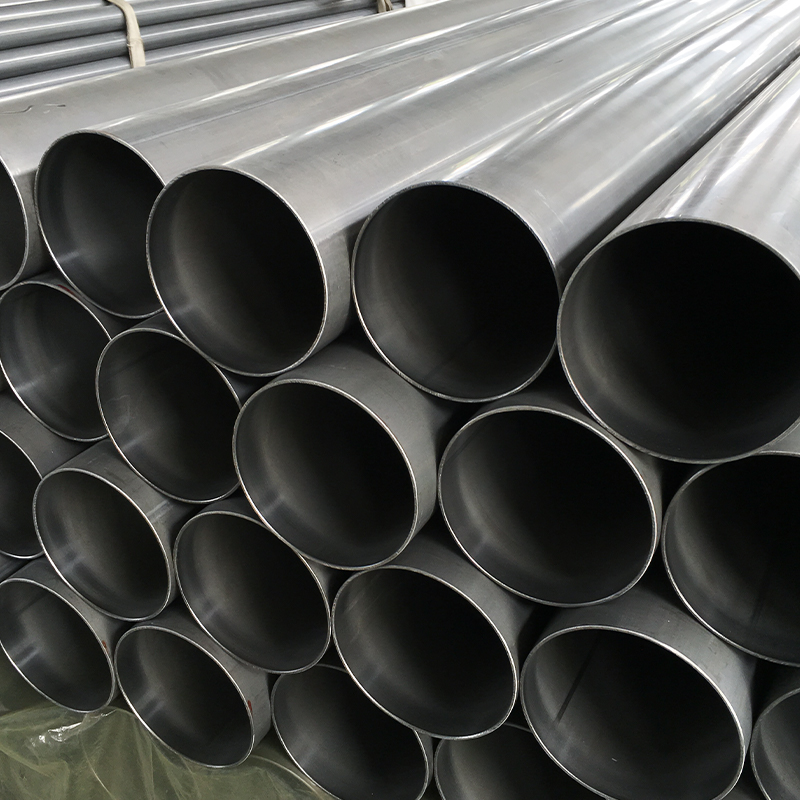

Our Welded Hydraulic Tubes are produced from cold-drawn or ERW-welded strip steel in compliance with EN 10305-2 precision tube standards.They provide excellent dimensional control, straightness, and surface quality, making them suitable for hydraulic systems, pneumatic equipment, and industrial machinery.Compared to seamless tubes, welded tubes offer a cost-effective alternative for applications where extremely high-pressure resistance is not critical but dimensional accuracy and surface quality are still required.

Key Features

·Standard: EN 10305-2 (Welded Precision Tubes)

·Material: SPHC, E215, E235, E355

·Processes: Cold Drawn Welded (CDW), ERW

·High dimensional accuracy and straightness

·Smooth inner surface suitable for sealing & hydraulic fittings

·Cost-effective compared to seamless tubes

·Optional surface treatments: phosphated, oiled, e-coated

Technical Specifications

|

Parameter

|

Specification

|

|

Standard

|

EN 10305-2

|

|

Steel Grades

|

SPHC, E215, E235, E355

|

|

OD Range

|

Ø10 – 100 mm

|

|

Wall Thickness

|

1 – 10 mm

|

|

Delivery Condition

|

As-drawn or +N (Normalized optional)

|

|

Tolerance

|

EN 10305-2 standard

|

|

Surface Finish

|

Oiled, phosphated, e-coated optional

|

|

Length

|

Up to 12 m (cut-to-length available)

|

Common Sizes

·Ø12 x 2 mm

·Ø20 x 2.5 mm

·Ø30 x 3 mm

·Ø50 x 5 mm

·Ø76 x 6 mm

·Ø90 x 8 mm

(Custom sizes available on request)

Manufacturing Process

1. Steel Strip Selection – SPHC / E215 / E235 / E355

2. Forming & Welding – ERW or CDW process

3. Cold Drawing – improves dimensional accuracy

4. Heat Treatment – optional normalization for stability

5. Surface Treatment – oiling, phosphating, e-coating

6. Inspection & Testing – dimensional check, straightness, weld integrity

Advantages

·Lower cost compared to seamless tubes

·High dimensional accuracy & straightness

·Good surface finish for sealing & hydraulic applications

·Wide diameter and wall thickness range

·Suitable for industrial, agricultural, and construction machinery

Applications

·Hydraulic and pneumatic systems

·Agricultural machinery & equipment

·Construction machinery

·Industrial hydraulic systems

·Medium-pressure hydraulic cylinders

English

English Español

Español русский

русский