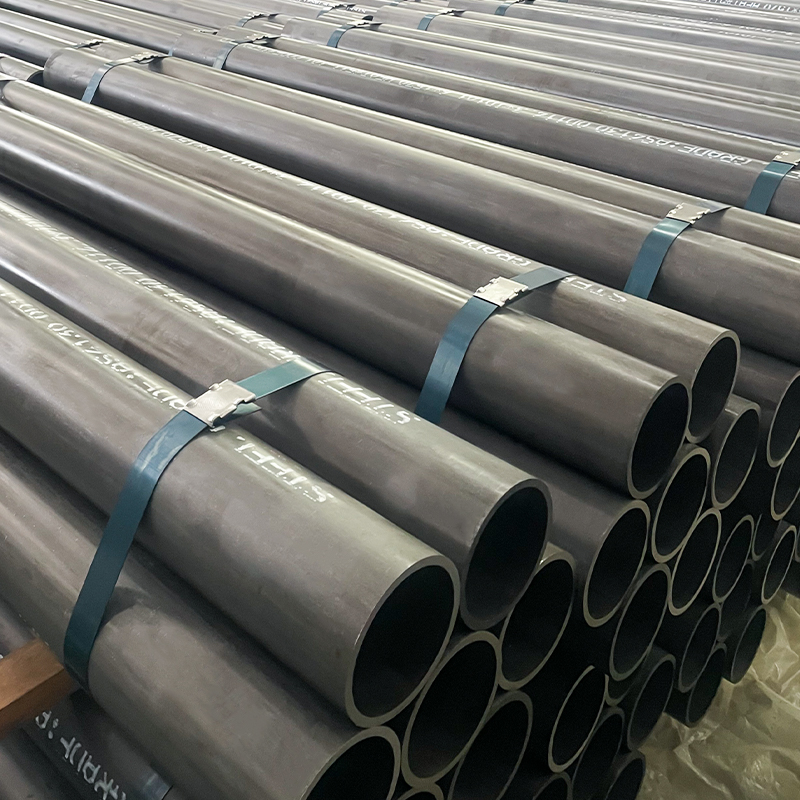

Why Cold-Drawn Tubes Outperform Hot-Rolled in Precision Applications

The fundamental difference between cold-drawn and hot-rolled steel tubes lies in their manufacturing temperature and resulting mechanical properties. Cold drawing occurs at room temperature, work-hardening the material and creating a tighter grain structure. This process delivers superior dimensional accuracy, with typical tolerances reaching ±0.05mm for outer diameter and ±0.1mm for wall thickness—far exceeding what hot-rolled processes can achieve.

Key advantages include:

- Surface finish quality: Cold-drawn tubes achieve Ra 0.4–1.6μm roughness without additional machining, eliminating surface oxidation common in hot-rolled products

- Enhanced tensile strength: The cold-working process increases tensile strength by 15–30% compared to equivalent hot-rolled grades

- Straightness control: Typical straightness of ≤1mm/m makes cold-drawn tubes ideal for hydraulic cylinders and precision shafts

With our proprietary multi-pass cold drawing technology and real-time dimensional monitoring, we consistently deliver tubes that meet the most demanding specifications for hydraulic systems, automotive components, and precision machinery.

Understanding DIN 2391 vs. EN 10305 Standards for Hydraulic Tubes

Selecting the correct standard ensures compatibility with your hydraulic system's pressure requirements and assembly methods. While both DIN 2391 and EN 10305 govern precision cold-drawn seamless steel tubes, they serve distinct applications.

DIN 2391 (Seamless Precision Steel Tubes)

This German standard specifies cold-drawn tubes with controlled dimensional tolerances specifically for hydraulic and pneumatic applications. Key characteristics:

- Normalized or stress-relieved heat treatment mandatory for improved machinability

- Tighter wall thickness tolerance (typically ±10% of nominal)

- Surface quality suitable for direct honing without intermediate machining

EN 10305 (Multiple Parts for Different Forming Methods)

This European standard encompasses several sub-specifications:

- EN 10305-1: Seamless cold-drawn tubes for general precision applications

- EN 10305-4: Seamless cold-drawn tubes specifically for hydraulic and pneumatic power systems, closely aligned with DIN 2391

Our production lines are certified to manufacture tubes meeting both standards, and our technical team can guide you through material selection based on your operating pressures, which typically range from 160 bar for industrial hydraulics to 400+ bar for mobile equipment.

Heat Treatment Options and Their Impact on Tube Performance

Post-drawing heat treatment fundamentally alters the mechanical properties of cold-drawn steel tubes. Understanding these treatments helps optimize tubes for specific applications.

Stress Relieving (SR)

Heating to 550–650°C removes internal stresses from cold working while maintaining high strength. Results in minimal dimensional change during subsequent machining and prevents warping during welding operations.

Normalized (N)

Heating above the upper critical temperature (typically 880–950°C) followed by air cooling produces a uniform, fine-grained structure. This treatment improves machinability by reducing hardness to 120–180 HB while maintaining adequate strength for most hydraulic applications.

Normalized + Tempered (N+T)

Combines normalization with subsequent tempering (500–650°C) to achieve optimal balance between strength and ductility. Commonly specified for high-pressure hydraulic systems operating above 350 bar.

Bright Annealed (BK/BKW)

Annealing in controlled atmosphere prevents surface oxidation, producing tubes with excellent surface brightness and reduced hardness for forming operations. The "BKW" designation indicates a subsequent light cold-drawing pass for improved dimensional accuracy.

Our in-house heat treatment facilities with automated atmosphere control ensure consistent metallurgical properties across every production batch, eliminating the quality variations common when outsourcing this critical process.

Critical Tolerance Specifications for Hydraulic Cylinder Tubes

Hydraulic cylinder tubes demand tighter tolerances than general mechanical tubes to ensure proper seal function, minimize internal leakage, and enable precision honing. Understanding these requirements prevents costly rework and assembly failures.

Outer Diameter Tolerance: Standard cold-drawn tubes offer ±0.2mm, but hydraulic applications typically require ±0.1mm or tighter. For tubes intended for direct honing, we maintain ±0.05mm OD tolerance to minimize material removal and preserve wall thickness uniformity.

Wall Thickness Tolerance: Inconsistent wall thickness creates weak points under pressure. Hydraulic specifications typically demand ±10% of nominal wall thickness. For example, a 5mm wall tube should maintain 4.5–5.5mm throughout its length, with local variation not exceeding 12.5%.

Ovality (Out-of-Roundness): Excessive ovality prevents uniform seal contact and accelerates wear. Quality hydraulic tubes limit ovality to ≤0.5% of outer diameter. For a 100mm OD tube, this means maximum deviation of 0.5mm between maximum and minimum diameters.

Straightness: Bent tubes complicate assembly and create uneven stress distribution. Standard specification is ≤1.5mm/m, but precision hydraulic cylinders require ≤1mm/m or 0.5mm/m for servo applications.

Our online laser measurement systems inspect 100% of production, automatically flagging and segregating any tubes outside specification—ensuring you receive only tubes that meet your exact requirements.

Material Grade Selection: E235 vs. E355 vs. ST52 for Different Loading Conditions

Choosing the appropriate steel grade balances cost, strength requirements, and machinability. Here's how common grades compare:

E235 (Similar to ST37, STKM13A)

- Minimum yield strength: 235 MPa

- Excellent weldability and formability

- Suitable for low to medium-pressure hydraulics (≤160 bar) and structural applications

- Most economical option for general machinery components

E355 (Similar to ST52, STKM15A)

- Minimum yield strength: 355 MPa

- Standard choice for medium to high-pressure hydraulics (160–350 bar)

- Good balance of strength, toughness, and cost

- Widely specified in construction equipment, agricultural machinery, and industrial presses

ST52 / ST52.3

- The ".3" designation indicates normalized condition with improved impact properties

- Minimum Charpy V-notch impact: 27J at 20°C

- Preferred for mobile hydraulics operating in variable temperature environments

For specialized applications requiring even higher strength (e.g., 42CrMo4, 34CrMo4), we offer alloy steel tubes with yield strengths exceeding 650 MPa after quenching and tempering—ideal for heavy-duty excavators, mining equipment, and ultra-high-pressure systems.

The Role of Non-Destructive Testing in Quality Assurance

Hidden defects in hydraulic tubes can lead to catastrophic failures under pressure. Non-destructive testing (NDT) methods detect these flaws without compromising the tube integrity.

Eddy Current Testing (ECT)

Electromagnetic induction detects surface and near-surface defects including cracks, seams, and laps. Our automated ECT systems inspect 100% of tube surface area at production speeds up to 60 meters/minute, with sensitivity to defects as small as 0.3mm deep.

Ultrasonic Testing (UT)

High-frequency sound waves identify internal defects such as inclusions, porosity, and laminations. Particularly critical for thick-walled tubes where internal quality cannot be verified visually. We employ both pulse-echo and through-transmission UT methods depending on tube geometry and specification requirements.

Hydrostatic Pressure Testing

Physical proof testing where tubes are pressurized to 1.5× the rated working pressure and held for specified duration (typically 5–10 seconds). While destructive if failure occurs, this confirms structural integrity under actual operating stresses.

Our comprehensive NDT protocols exceed standard industry requirements, and we maintain full traceability with automated data logging for every tested tube—documentation that's increasingly required for liability-critical applications.

Surface Treatment Options for Extended Service Life

While cold-drawn seamless steel tubes offer excellent base surface quality, additional treatments can significantly enhance corrosion resistance and reduce friction for specific applications.

Phosphating

Creates a crystalline conversion coating that improves paint adhesion and provides temporary corrosion protection during storage and shipping. Particularly valuable for tubes that will undergo powder coating or wet painting as final finish.

Black Oxide (Blackening)

Chemical conversion process producing a black magnetite finish. Provides minimal dimensional change (typically <0.01mm) while offering moderate corrosion resistance and reduced light reflection. Common for hydraulic piston rods and visible machinery components.

Zinc Plating

Electroplated zinc coating (typically 5–15μm thickness) provides superior corrosion protection. Available in clear, yellow, or black chromate finishes. Critical consideration: zinc thickness must be accounted for in dimensional tolerances, especially for tubes requiring subsequent honing to H8 or H9 tolerances.

Oil Coating

Application of rust-preventive oil provides economical short-term protection (typically 3–6 months indoor storage). We offer both standard mineral oil and water-soluble oil coatings depending on your cleaning process compatibility.

As a vertically integrated manufacturer, we coordinate surface treatment timing within our production flow to optimize both protection and dimensional control—something that's difficult to achieve when treatments are outsourced.

English

English Español

Español русский

русский