Cold Drawn Seamless (CDS) steel tubes manufactured according to EN 10305-1, available in grades E235 and E355. These precision tubes offer tight dimensional tolerances, smooth internal/external surfaces, and excellent mechanical properties, making them ideal for high-performance engineering and industrial applications.

Key Features:

·Manufactured to EN 10305-1 in grades E235 / E355

·Superior dimensional accuracy and roundness

·Smooth surface finish suitable for honing, SRB, or plating

·High strength with good machinability and weldability

·Custom lengths and machining available

Applications:

Hydraulic and pneumatic systems, automotive components, shock absorbers, drive shafts, mechanical engineering, and structural assemblies.

Technical Specifications

|

Specification

|

Details

|

|

Standard

|

EN 10305-1

|

|

Grades Available

|

E235, E355

|

|

Equivalent Standards

|

DIN 2391, ASTM A519, ISO 8535-1

|

|

Outside Diameter (OD)

|

10 mm – 350 mm (custom on request)

|

|

Wall Thickness (WT)

|

1 mm – 30 mm

|

|

Lengths Available

|

Up to 12 m or cut-to-size

|

|

Surface Condition

|

As-drawn / Honed / SRB (Skived & Roller Burnished)

|

|

Tolerance

|

ISO h8 / h9 or per customer request

|

|

Supply Condition

|

Normalized (NBK), Annealed (BK), Stress Relieved (BKS)

|

Industries Served

·Automotive & Commercial Vehicles

·Hydraulic & Pneumatic Systems

·Heavy Machinery & Construction Equipment

·Energy & Power Generation

·General Mechanical Engineering

Call to Action

·Looking for Cold Drawn Seamless Steel Tubes in EN 10305-1 E235 / E355?

Contact us today for a quotation. Custom sizes, machining, and surface treatments are available upon request.

·Cold Drawn Seamless (CDS) steel tubes manufactured according to EN 10305-1 and ASTM A519 standards. Available in a wide range of carbon and alloy steel grades, including E235, E355, ST52.3, AISI 1045, 4130, and 4140.

·These tubes feature high dimensional accuracy, superior mechanical strength, and excellent surface quality, making them suitable for hydraulic cylinders, automotive components, drive shafts, and industrial machinery.

Key Features:

·Precision manufacturing to EN 10305-1 / ASTM A519

·Carbon steel grades: E235, E355, ST52.3,AISI 1045

·Alloy steel grades: AISI 4130, AISI 4140, AISI 4340

·Smooth surface finish for honing, SRB, or plating

·Tight tolerances for precision engineering applications

·Available in custom lengths and heat-treated conditions

Applications:

Hydraulic and pneumatic cylinders, shock absorbers, automotive drive shafts, construction equipment, machine components, and heavy-duty engineering assemblies.

Technical Specifications

|

Specification

|

Details

|

|

Standards

|

EN 10305-1, ASTM A519, DIN 2391, ISO 8535-1

|

|

Carbon Steel Grades

|

E235, E355, ST37.2, ST52.3, AISI 1020, AISI 1045

|

|

Alloy Steel Grades

|

AISI 4130, AISI 4140, AISI 4340

|

|

Stainless Options

|

Available on request (AISI 304 / 316)

|

|

Outside Diameter (OD)

|

10 mm – 350 mm (custom sizes available)

|

|

Wall Thickness (WT)

|

1 mm – 30 mm

|

|

Lengths Available

|

Up to 12 m, cut-to-length supply available

|

|

Surface Condition

|

As-drawn, Honed, SRB (Skived & Roller Burnished), Chrome Plated

|

|

Tolerance

|

ISO h8 / h9 or per customer request

|

|

Supply Condition

|

BK (Cold Finished), NBK (Normalized), BKS (Stress Relieved), Q+T (Heat Treated)

|

Downloads

·[Product Datasheet PDF]

·[Material Test Certificate (EN 10204 3.1)]

·[CAD Drawing Request]

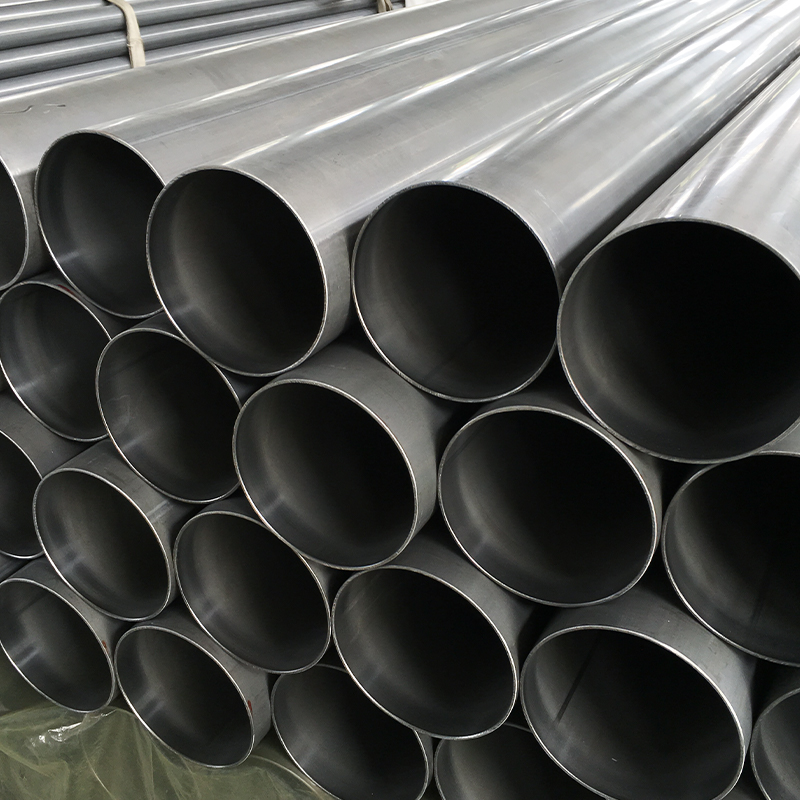

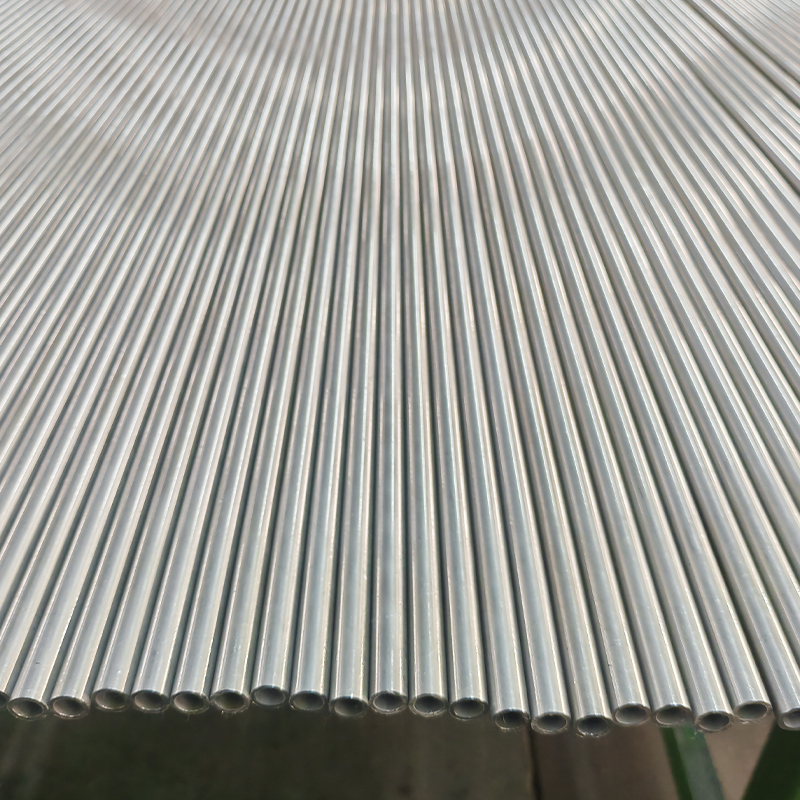

Gallery / Visuals

·Bundled tube packages (export packing)

·Surface finish close-up (inside & outside)

·Application example (hydraulic cylinder / automotive shaft)

·Technical cross-section diagram

Industries Served

·Automotive & Commercial Vehicles

·Hydraulic & Pneumatic Systems

·Oil & Gas & Energy Equipment

·Heavy Machinery & Construction

·Mechanical & Structural Engineering

English

English Español

Español русский

русский