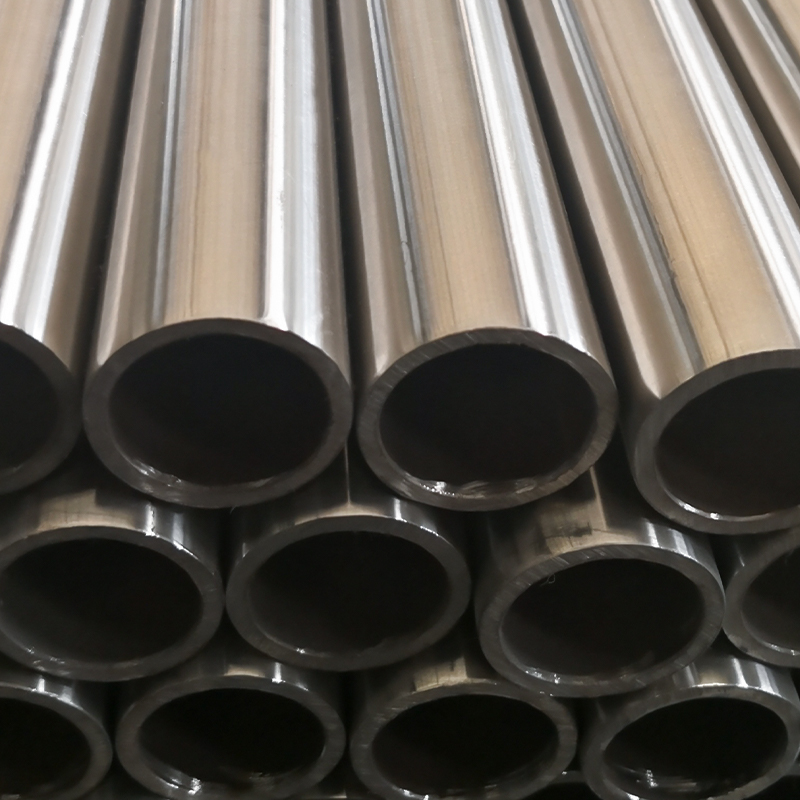

Why Cold Drawing Produces Superior Dimensional Accuracy Over Hot Rolling

Cold drawing achieves tolerances as tight as ±0.05mm through controlled deformation at room temperature, whereas hot-rolled tubes typically hold ±0.5mm or wider. This precision stems from three key factors:

- Elimination of thermal expansion variables—material dimensions remain stable without heat-induced fluctuations

- Controlled die reduction allows incremental size refinement through multiple passes

- Work hardening creates uniform wall thickness with minimal eccentricity (typically <5%)

For hydraulic cylinders, pneumatic systems, and precision machinery, this dimensional consistency translates directly to reduced assembly rejection rates and longer service life. Our automated measuring systems monitor every cold drawn stainless steel tubing at 0.001mm resolution during production, ensuring batch-to-batch consistency that machining operations demand.

Material Selection: 304 vs 316L in Corrosive Hydraulic Environments

While both grades offer austenitic stainless properties, the choice between 304 and 316L determines system longevity in specific chemical exposures:

304 Stainless Steel

- Optimal for freshwater, atmospheric, and mild chemical service

- Cost-effective for indoor hydraulic systems with mineral-based fluids

- Susceptible to pitting in chloride concentrations above 200ppm

316L Stainless Steel

- 2-3% molybdenum addition provides superior chloride resistance—essential for marine and coastal installations

- Lower carbon content (0.03% max) eliminates sensitization risk during welding

- Recommended for phosphate ester fluids and water-glycol systems

We maintain dedicated production lines for both grades, with rigorous PMI testing to prevent cross-contamination—a critical concern when tubes are specified for critical pharmaceutical or food-grade applications.

Understanding Annealing Cycles and Their Impact on Tube Performance

Cold drawing increases material hardness from ~150HV to 250-300HV, which improves structural strength but reduces formability. Strategic heat treatment restores specific properties:

- Bright annealing (1040-1120°C in protective atmosphere)—preserves surface finish while reducing hardness to 140-180HV for subsequent bending or flaring operations

- Solution annealing (1050-1150°C with rapid quenching)—dissolves carbide precipitates, restoring maximum corrosion resistance

- Stress relieving (300-450°C)—eliminates residual stresses without significantly altering hardness

For tubes requiring both high strength and moderate formability, we offer controlled partial annealing that retains 70-80% of cold-worked strength while improving ductility by 40%. Our continuous bright annealing furnaces use hydrogen-nitrogen atmospheres to maintain mirror-like ID finishes down to Ra 0.2μm—critical for minimizing turbulence in high-pressure hydraulic circuits.

Wall Thickness Optimization: Balancing Pressure Rating and Weight Reduction

The relationship between wall thickness and allowable working pressure follows Barlow's formula, but practical applications require additional safety margins:

P = 2St / D (where P=pressure, S=allowable stress, t=wall thickness, D=outside diameter)

For 316L stainless at 200°C service temperature with S=138MPa, a 25mm OD tube requires:

- 1.5mm wall → 16.5MPa working pressure (suitable for pneumatic applications)

- 2.5mm wall → 27.6MPa working pressure (standard industrial hydraulics)

- 3.5mm wall → 38.6MPa working pressure (high-pressure injection molding systems)

However, reducing wall from 3.5mm to 2.5mm achieves 29% weight savings—significant for mobile machinery and aerospace applications. Our engineering team provides pressure-temperature charts customized to your fluid type and safety factor requirements, helping specify the minimum safe wall thickness for cost optimization.

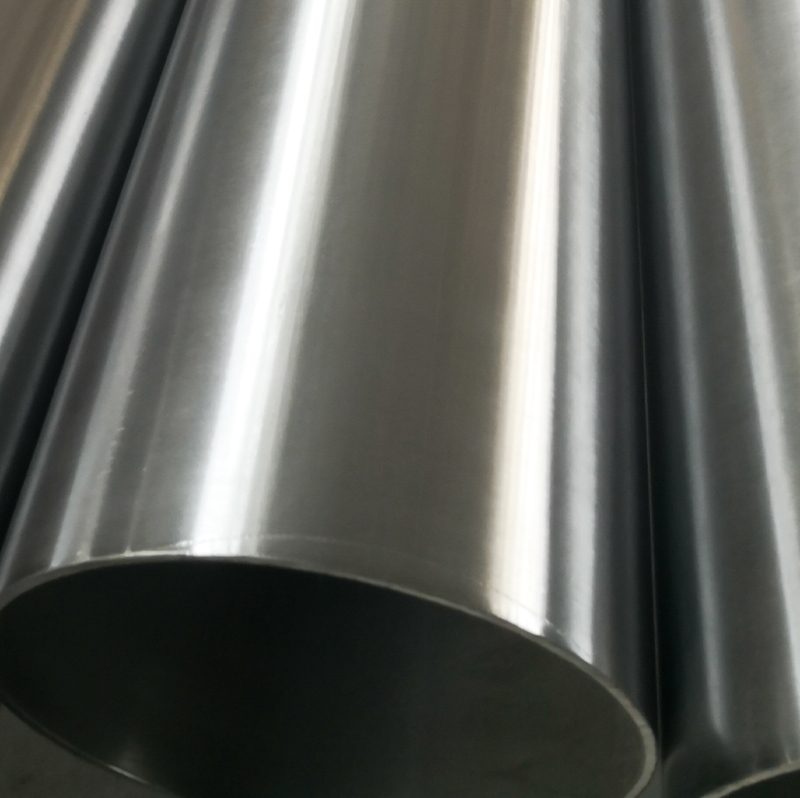

Surface Finish Specifications: When Ra Values Actually Matter

Interior surface roughness directly affects three performance parameters in precision applications:

Hydraulic Efficiency

Reducing ID roughness from Ra 1.6μm to Ra 0.4μm decreases friction factor by approximately 15% in turbulent flow regimes (Reynolds number >4000). This translates to measurable energy savings in systems operating above 15 L/min flow rates.

Seal Compatibility

O-ring and U-cup seals require Ra 0.8μm or finer to prevent premature wear—rougher surfaces create friction points that generate heat and abrasive particles. For reciprocating applications exceeding 1m/s velocities, we recommend honed bores at Ra 0.2-0.4μm.

Contamination Control

Smoother surfaces reduce particle adhesion—critical for pharmaceutical clean-steam systems and semiconductor chemical delivery. Our electropolishing process achieves Ra 0.15μm while removing 20-30μm of surface material, eliminating embedded contaminants from manufacturing.

Non-Destructive Testing: What Each Method Actually Detects

Different NDT techniques reveal distinct flaw types. Comprehensive quality assurance requires understanding their respective capabilities:

- Eddy current testing—detects surface and near-surface cracks down to 0.5mm depth, plus wall thickness variations. Effective on non-ferromagnetic stainless steels at production speeds up to 60m/min

- Ultrasonic testing—identifies internal laminations, inclusions, and through-wall defects. Our immersion UT systems scan 100% tube volume with 1mm flaw detection sensitivity

- Hydrostatic testing—verifies pressure integrity but cannot detect flaws smaller than critical crack size. We test at 1.5× design pressure for 30 seconds minimum

- PMI analysis—confirms material chemistry, preventing costly grade mix-ups. Takes 5-8 seconds per measurement point

For critical applications like nuclear piping or aircraft hydraulics, we combine multiple methods—eddy current for surface integrity, UT for volumetric inspection, and PMI for traceability. Every cold drawn stainless steel tube leaving our facility carries certification traceable to raw material heat numbers and individual test results.

Straightness Tolerances and Their Effect on Assembly Fit

Standard commercial straightness of 1.5mm per meter may seem adequate on paper, but creates measurable problems in precision assemblies:

- Hydraulic cylinders with 6-meter stroke lengths accumulate 9mm potential misalignment, causing piston seal drag and uneven wear

- Multi-port manifold connections require shimming or rework when tube bows exceed fitting tolerances

- Automated welding systems cannot maintain consistent torch-to-joint distance on curved tubes

We offer enhanced straightness grades down to 0.3mm/meter through precision roller straightening with closed-loop measurement. This five-fold improvement eliminates field adjustments in robotic assembly lines and ensures hydraulic piston rods slide freely without binding—particularly important in high-cycle applications exceeding 1 million strokes.

For extreme precision requirements such as telescope actuators or semiconductor lithography stages, our centerless grinding process achieves 0.05mm/meter straightness while maintaining micron-level diameter consistency.

English

English Español

Español русский

русский