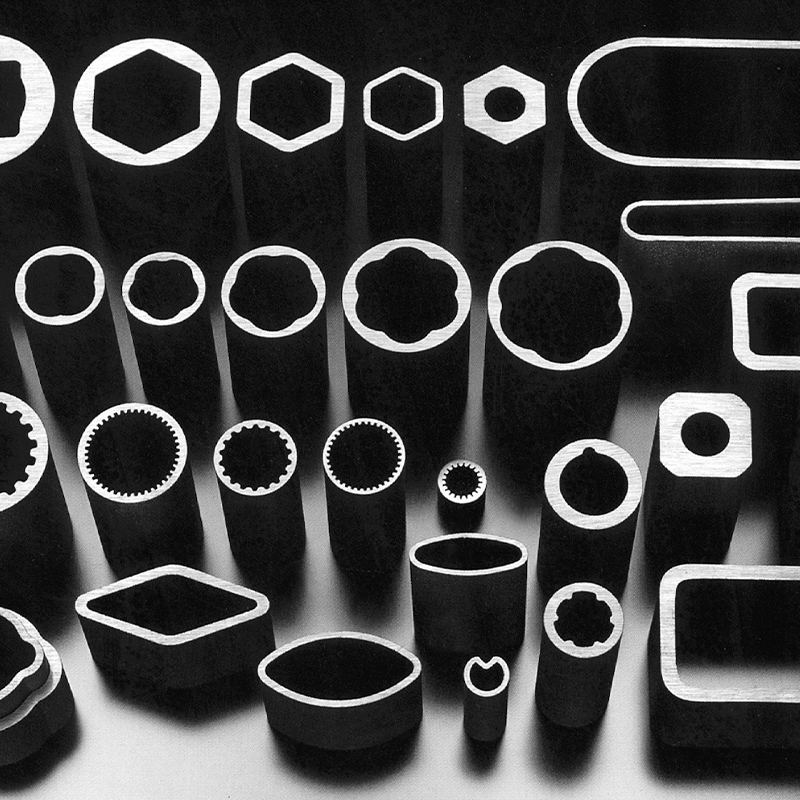

Special shaped steel pipes are widely applied in mechanical structures and load-bearing systems where standard round tubing cannot meet functional or spatial requirements. Precise control of cross-sectional geometry directly affects load distribution, assembly accuracy, and structural stability. Profiles such as rectangular, oval, multi-lobed, or customized shapes are often designed to improve torsional resistance or to integrate multiple functions within a single component.

Cold drawing combined with online dimensional monitoring allows consistent shape accuracy along the entire pipe length, supporting stable performance in applications that demand tight geometric tolerances.

Cold Drawing Advantages for Complex Cross Sections

For special shaped steel pipes, cold drawing plays a key role in achieving sharp profile definition and uniform wall thickness. Compared with welded or hot-formed profiles, cold-drawn pipes offer improved surface quality and dimensional consistency, which simplifies downstream machining and assembly.

Wall Thickness Control and Stress Distribution

Uniform wall thickness is essential for predictable stress distribution under dynamic loads. Controlled drawing and subsequent heat treatment help balance strength and ductility, allowing special shaped pipes to perform reliably in automotive structural parts, construction machinery frames, and railway components exposed to vibration and cyclic stress.

Functional Integration Through Profile Design

One practical advantage of special shaped steel pipes is their ability to integrate multiple functions into a single component. Customized profiles can reduce the need for secondary welding or assembly steps by incorporating guiding surfaces, mounting features, or reinforcement zones directly into the pipe design.

This approach supports lightweight design while maintaining structural strength, which is particularly valuable in automotive parts, wind energy equipment, and shipbuilding structures.

Industry-Specific Applications of Special Shaped Steel Pipes

Different industries adopt special shaped steel pipes based on functional and structural priorities. Flexible production systems enable manufacturers to deliver both standardized profiles and customized designs for diverse industrial sectors.

| Industry Sector |

Application Focus |

| Automotive |

Lightweight structures and component integration |

| Construction Machinery |

High rigidity frames and load-bearing elements |

| Wind Energy |

Structural supports under cyclic loads |

| Railways |

Vibration resistance and dimensional stability |

Surface Treatment and Finishing Considerations

Surface treatment is an important factor in extending the service life of special shaped steel pipes. Processes such as controlled finishing, chamfering, and protective coatings help improve corrosion resistance and handling safety during installation.

Integrated finishing capabilities ensure that complex profiles maintain edge consistency and dimensional accuracy after cutting and surface processing, supporting efficient assembly in industrial production environments.

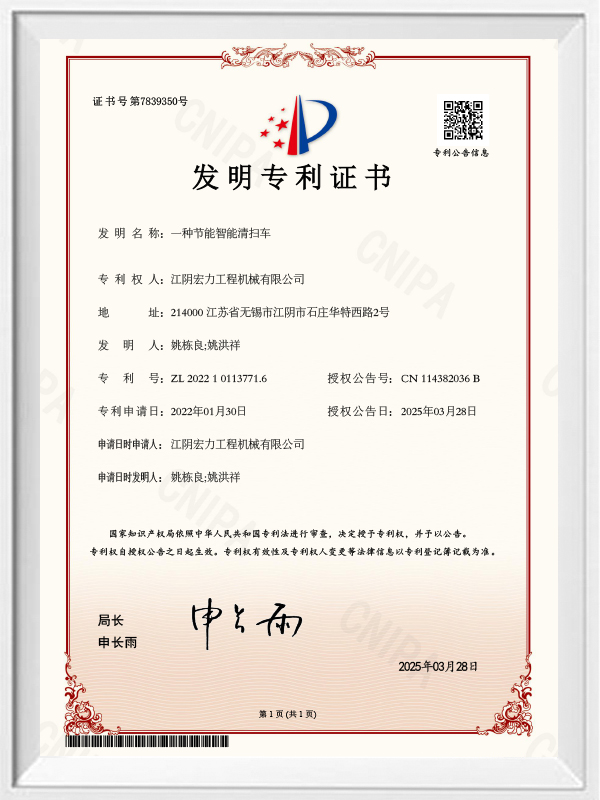

Quality Control and Manufacturing Flexibility

Consistent quality in special shaped steel pipe production relies on comprehensive inspection and process control. Non-destructive testing methods, combined with chemical analysis, help verify material integrity without affecting product performance.

With integrated R&D, production, and inspection systems, manufacturers capable of flexible, high-mix, low-volume production can respond efficiently to customized profile requirements while meeting international standards such as ISO 9001, ISO 14001, CE, and RoHS. This level of manufacturing integration supports long-term collaboration with global industrial clients.

English

English Español

Español русский

русский