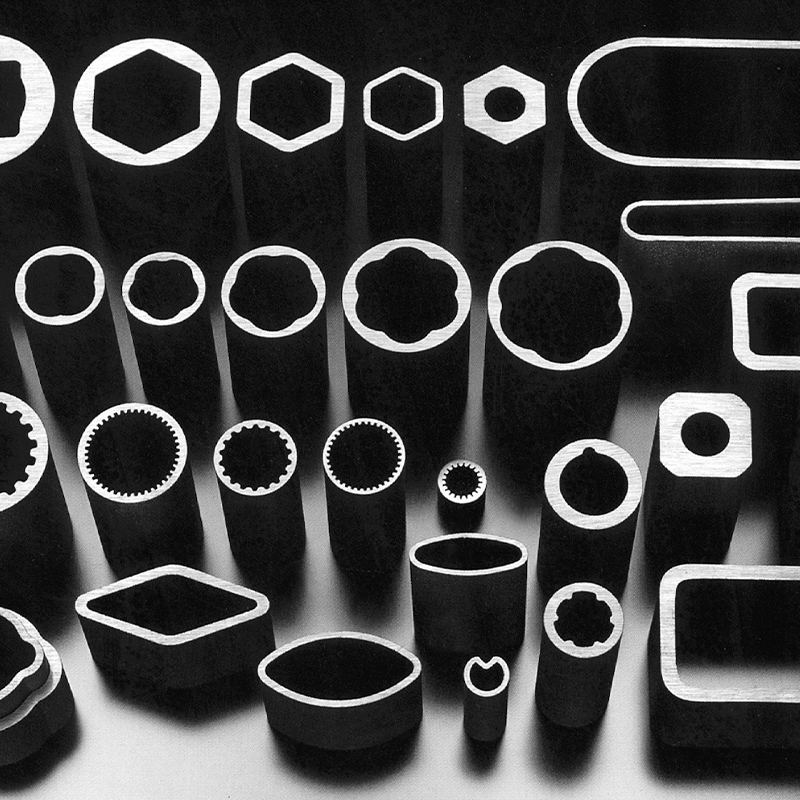

Our Special Shaped Steel Pipes are designed for applications requiring custom profiles that standard round tubes cannot provide.

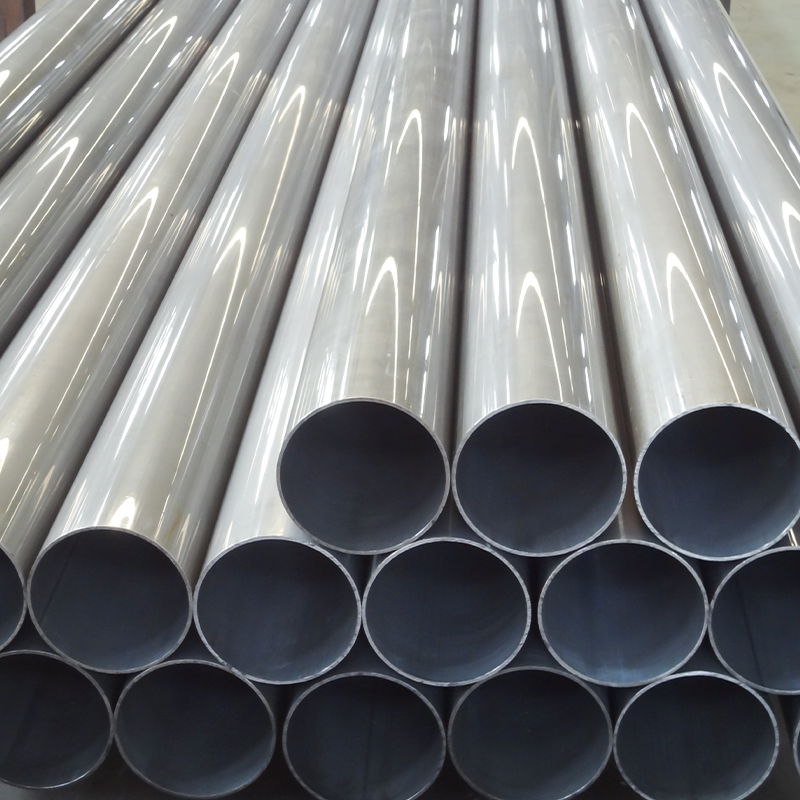

Manufactured from high-quality steel and produced via cold forming or hot rolling, these tubes meet EN 10296-2 standards for dimensional accuracy and mechanical properties.

They are widely used in:

·Structural engineering

·Automotive frames and chassis

·Industrial machinery

·Construction equipment

Key Features

·Custom profiles: square, rectangular, oval, or other shapes

·Manufacturing: Cold Formed or Hot Rolled

·Standard: EN 10296-2

·High dimensional accuracy and straightness

·Excellent surface quality

·Suitable for welding, machining, or assembly

Technical Specifications

|

Parameter

|

Specification

|

|

Standard

|

EN 10296-2

|

|

Steel Grades

|

S235, S275, S355, ST52 (custom grades available)

|

|

Profiles

|

Square, Rectangular, Oval, Custom

|

|

Wall Thickness

|

2 – 20 mm (depending on profile)

|

|

OD / Dimensions

|

Custom sizes available

|

|

Manufacturing Method

|

Cold Formed / Hot Rolled

|

|

Surface Finish

|

Oiled, pickled, or as-rolled

|

|

Length

|

Up to 12 m (cut-to-length available)

|

Manufacturing Process

1. Steel selection according to required grade and mechanical properties

2. Cold forming for precise dimensional control or hot rolling for larger profiles

3. Straightening and cutting to length

4. Optional surface treatments: oiled, pickled, or coated

5. Inspection: dimensional checks, straightness, profile accuracy

Applications

·Structural frameworks and supports

·Automotive chassis, frames, and reinforcements

·Industrial machinery components

·Construction and agricultural equipment

·Custom engineering projects requiring non-standard profiles

Advantages

·Wide variety of custom shapes and sizes

·High dimensional accuracy and surface quality

·Can be welded, machined, or assembled easily

·Supports structural, automotive, and industrial applications

·Custom steel grades and thicknesses available

English

English Español

Español русский

русский