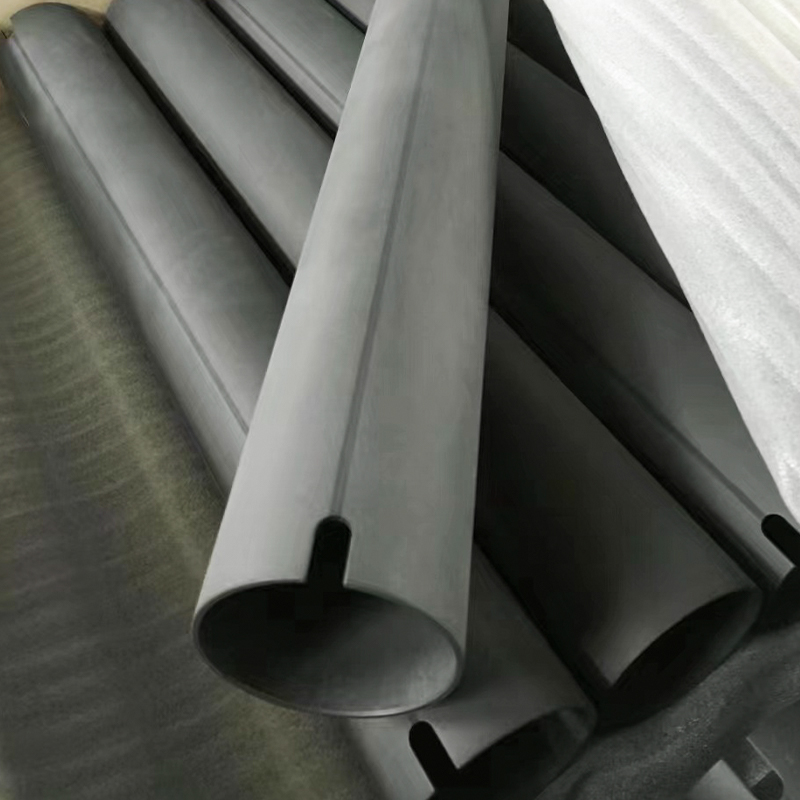

Why Surface Treatment Matters for Precision Steel Tubes

In high-performance mechanical and hydraulic systems, the base material alone rarely meets all operational demands. Surface-treated steel pipes—particularly those that are E-coated, phosphated, and oiled—offer enhanced corrosion resistance, improved lubricity during assembly, and better adhesion for subsequent coatings or paints. At Jiangsu Suao Metal Product Co., Ltd., we’ve integrated these treatments into our production flow to ensure our cold-drawn tubes perform reliably in harsh environments like offshore oil rigs or heavy construction machinery.

E-Coating: Uniform Protection Even in Complex Geometries

Electrophoretic coating (E-coating) uses an electric field to deposit a paint film evenly on conductive surfaces, including the inner bore of long steel tubes. Unlike spray painting, E-coating penetrates recesses and provides consistent thickness—typically 15–25 microns—without runs or sags. This makes it ideal for hydraulic cylinder tubes where internal corrosion can lead to seal failure. As a Surface-Treated Steel Pipes – E-Coated, Phosphated, and Oiled Manufacturer in China, we apply cathodic epoxy-based E-coats that meet ISO 9001 and RoHS standards, ensuring environmental compliance without sacrificing durability.

Key Advantages of E-Coated Steel Pipes

- Complete coverage, even on internal surfaces up to 6 meters in length

- Excellent resistance to salt spray (typically >500 hours per ASTM B117)

- Compatible with subsequent powder coating or bonding processes

Phosphating: Creating a Micro-Porous Foundation for Performance

Phosphating converts the steel surface into a layer of insoluble crystalline phosphate—usually zinc or manganese phosphate—which acts as a base for oil retention or paint adhesion. In hydraulic and pneumatic applications, this micro-porous structure holds lubricating oil, reducing friction during piston rod movement. Our phosphated tubes undergo strict control of crystal size (typically 5–10 µm) and coating weight (2.0–3.5 g/m²), verified through online monitoring systems at our 36,000 m² facility.

Common Phosphate Types and Their Industrial Uses

| Phosphate Type |

Coating Weight (g/m²) |

Primary Application |

| Zinc Phosphate |

2.0–3.5 |

Hydraulic cylinders, automotive components |

| Manganese Phosphate |

4.0–7.0 |

Heavy-duty gears, piston rods in mining equipment |

Oil Film Application: The Final Barrier Against Rust

After E-coating or phosphating, a thin layer of rust-preventive oil is often applied to provide immediate protection during storage and transport. We use low-viscosity, solvent-based oils that dry to a non-tacky film yet remain easily removable before final assembly. This step is critical for customers in shipbuilding or wind energy sectors, where tubes may sit in humid ports for weeks before installation. As your trusted Surface-Treated Steel Pipes – E-Coated, Phosphated, and Oiled Factory in China, we tailor oil type and thickness based on your logistics timeline and end-use environment.

Best Practices for Handling Oiled Tubes

- Store indoors with humidity below 60% RH to prevent condensation under the oil film

- Wipe with lint-free cloth using mild alkaline cleaner before welding or bonding

- Avoid stacking without protective separators—oil can trap moisture between contact points

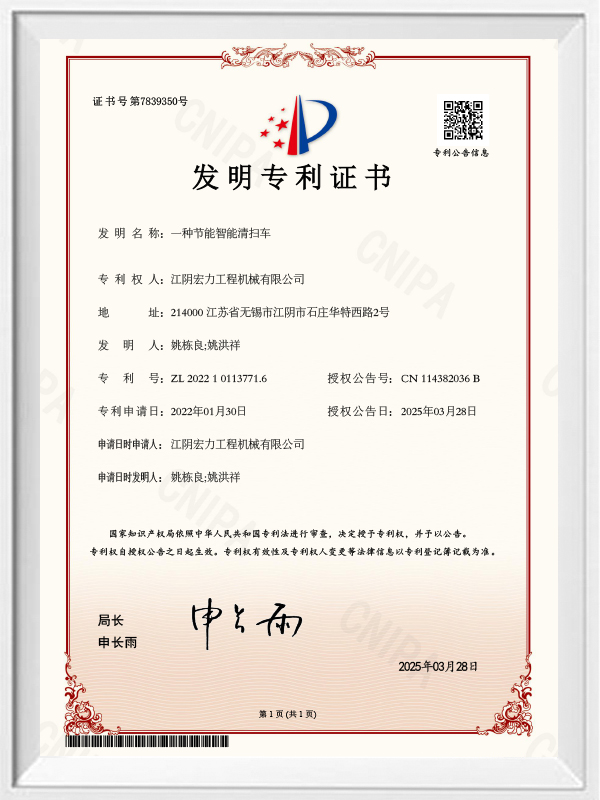

Integrated Surface Treatment in High-Mix Production

Unlike commodity tube suppliers, we design surface treatment sequences around your application—not the other way around. Need E-coated tubes with tight ID tolerances for telescopic cylinders? Or phosphated-and-oiled rods for railway brake systems? Our smart manufacturing system allows batch sizes as low as 500 kg while maintaining full traceability from billet to finished tube. With over 200 employees and advanced NDT capabilities, we ensure every Surface-Treated Steel Pipe – E-Coated, Phosphated, and Oiled – meets your exact functional requirements, not just dimensional specs.

English

English Español

Español русский

русский