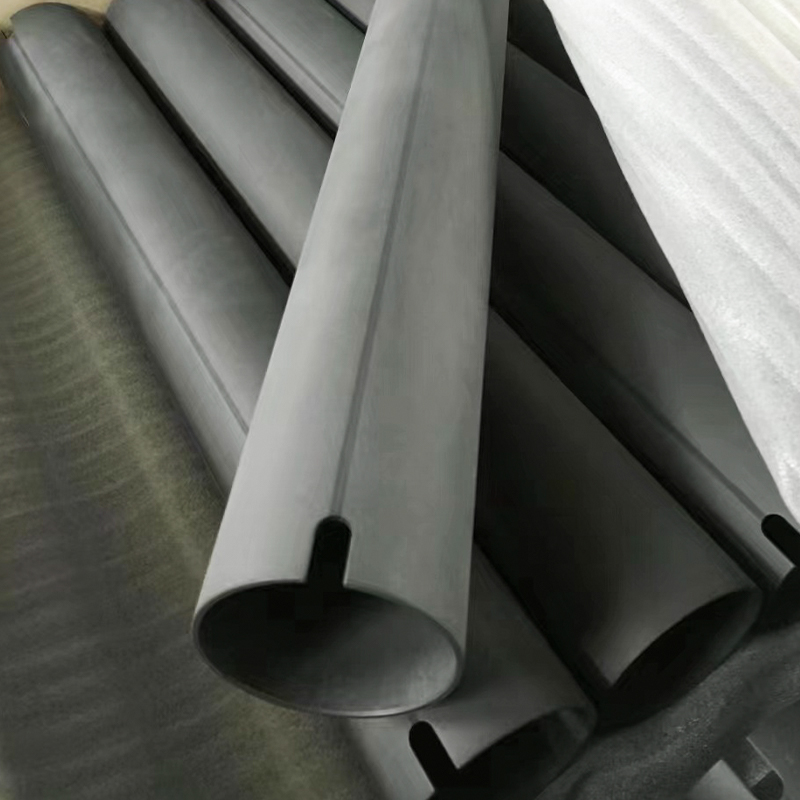

Our E-Coated Steel Pipes are treated with electro-coating (E-coating) to provide excellent corrosion resistance and a uniform black finish.These pipes are ideal for applications where durability, corrosion protection, and appearance are critical. The electro-coating process ensures that the coating penetrates crevices and internal surfaces, offering full protection compared to traditional surface coatings.

Applications include:

·Automotive structural components

·Construction and infrastructure projects

·Industrial machinery

·Outdoor piping and protective frameworks

Key Features

·Anti-corrosion electro-coating finish (black)

·Uniform coating on internal and external surfaces

·High adhesion and durability

·Suitable for welding, bending, or machining

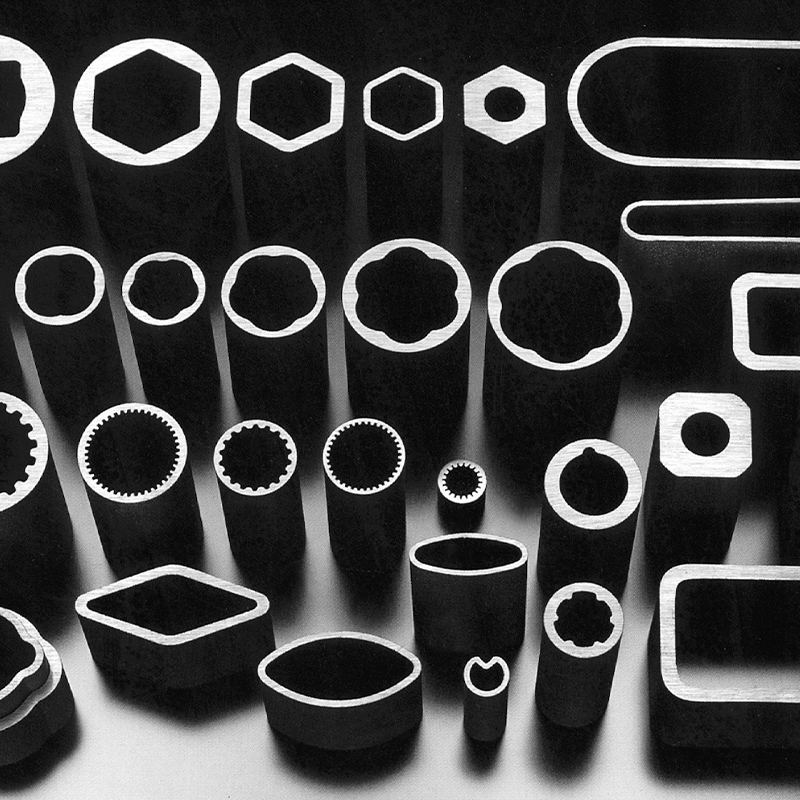

·Available in various steel grades and sizes

Technical Specifications Table

|

Parameter

|

Specification

|

|

Material / Steel Grade

|

S235, S275, ST52, or other carbon steel

|

|

Outer Diameter (OD)

|

Customizable, standard and metric sizes

|

|

Wall Thickness

|

1.5 – 12 mm (depending on application)

|

|

Coating Type

|

Electro-coating (E-Coating), Black

|

|

Corrosion Resistance

|

Excellent (passes ISO 9227 salt spray tests)

|

|

Surface Finish

|

Smooth, uniform, black

|

|

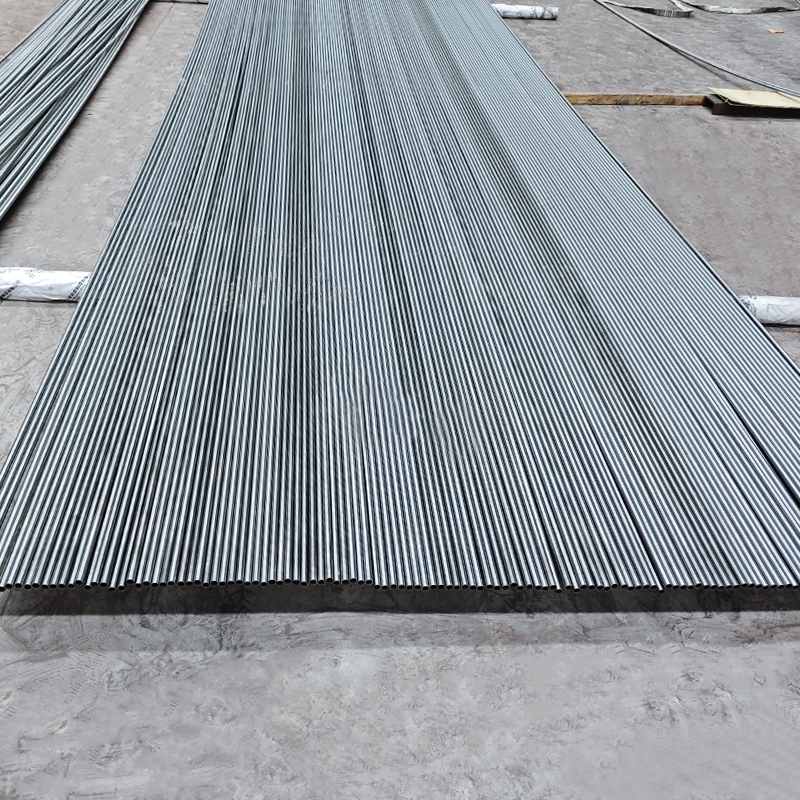

Length

|

Up to 12 m, cut-to-length available

|

Manufacturing Process

1. Steel pipe selection and preparation (cold-rolled or hot-rolled)

2. Surface cleaning and degreasing

3. Electro-coating immersion for full coverage

4. Curing in oven to ensure durable adhesion

5. Inspection – coating thickness, adhesion, and surface uniformity

Applications

·Automotive structural components and chassis

·Construction and civil engineering pipelines

·Industrial equipment and machinery

·Outdoor and corrosion-prone structures

·Furniture frames and protective tubing

Advantages

·Excellent corrosion resistance for long-term durability

·Uniform coating, including inner surfaces

·Compatible with welding, bending, or machining

·Provides aesthetic black finish for visible applications

·Can be combined with other protective coatings if needed

English

English Español

Español русский

русский