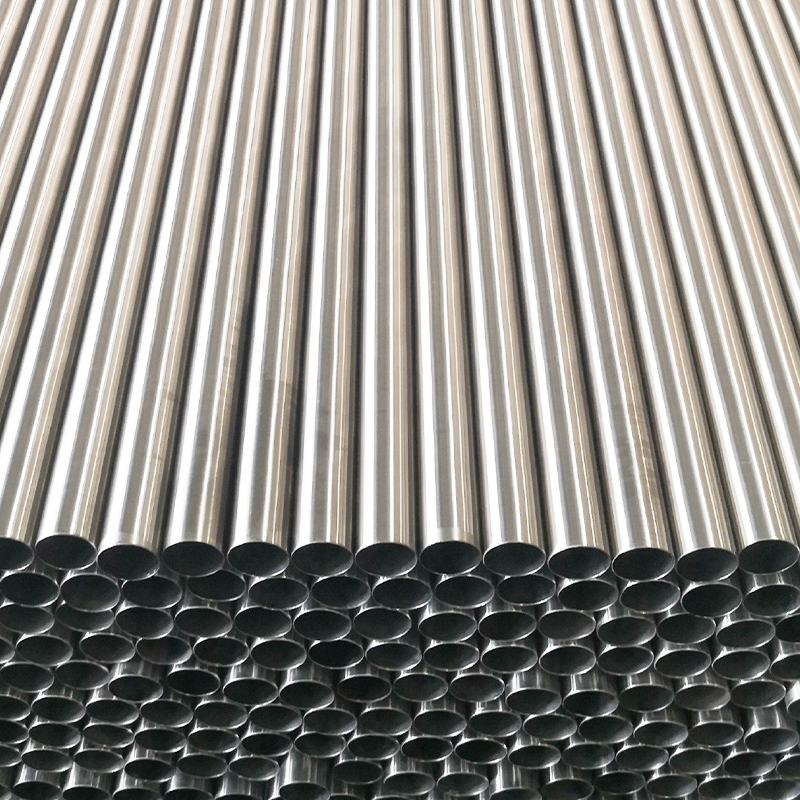

In real-world pneumatic systems, the performance of a Pneumatic Cylinder Tube is heavily influenced by inner diameter tolerance, straightness, and roundness. Even minor deviations can increase seal wear or cause uneven piston movement. For high-cycle automation lines, typical ID tolerances are controlled within H8–H9, while straightness is often maintained below 1/1000 of tube length. In our own production at Jiangsu Suao Metal Product Co., Ltd., we rely on online dimensional monitoring combined with cold drawing and straightening to keep these parameters stable across large batches, which is critical for downstream honing and assembly.

An often-overlooked detail is wall thickness uniformity. Variations here directly affect pressure resistance and fatigue life. This becomes especially important in compact cylinders where design margins are tight and operating pressures fluctuate rapidly.

Surface Treatments: Practical Differences for Pneumatic Cylinder Tube Performance

Beyond raw steel quality, surface treatment plays a major role in corrosion resistance and assembly efficiency. For Pneumatic Cylinder Tube manufacturing, Surface-Treated Steel Pipes – E-Coated, Phosphated, and Oiled are commonly selected based on storage conditions, installation environment, and lubrication strategy.

- E-Coated tubes provide uniform coverage inside and out, making them suitable for humid environments or export shipments with long transit times.

- Phosphated surfaces improve paint adhesion and initial lubricity, often used where secondary coating or welding follows.

- Oiled tubes focus on short-term corrosion protection and smooth machining, commonly preferred for fast-turnaround cylinder production.

As both Surface-Treated Steel Pipes – E-Coated, Phosphated, and Oiled Manufacturers and a dedicated Surface-Treated Steel Pipes – E-Coated, Phosphated, and Oiled Factory in China, we frequently help customers choose the most cost-effective option based on their actual process flow rather than generic specifications.

Material Selection and Heat Treatment Considerations

Common grades for Pneumatic Cylinder Tube production include E355, SAE 1026, and similar low-carbon steels optimized for cold drawing. However, mechanical behavior is just as dependent on heat treatment as on chemical composition. Stress-relieved or normalized tubes offer better dimensional stability during honing, while fully annealed tubes improve machinability for complex end-forming.

Integrated processes such as cold drawing followed by controlled heat treatment—something we run in-house across our 36,000+ square meter facilities—reduce variability between batches and simplify quality control for OEM cylinder manufacturers.

Typical Quality Control Items for Pneumatic Cylinder Tube Supply

For industrial buyers, incoming inspection usually focuses on more than just dimensions. Non-destructive testing and chemical verification are increasingly standard, especially in automotive and construction machinery sectors.

| Inspection Item |

Purpose |

Common Method |

| Eddy Current Testing |

Detect surface and sub-surface flaws |

Online automated scanning |

| Chemical Analysis |

Confirm steel grade compliance |

Spectrometer testing |

| Dimensional Measurement |

Ensure fit with seals and pistons |

Laser or mechanical gauges |

At Jiangsu Suao Metal Product Co., Ltd., these steps are embedded directly into production, supported by advanced equipment for non-destructive testing and chemical analysis, helping us deliver consistent Pneumatic Cylinder Tube quality across high-mix, low-volume orders.

Application-Specific Requirements Across Industries

Different sectors impose very different demands on Pneumatic Cylinder Tube products. In automotive parts, lightweight design and tight tolerances dominate. Construction machinery emphasizes impact resistance and long fatigue life. Wind energy and railways often prioritize corrosion protection due to outdoor exposure, while oil & gas applications focus on pressure stability and material traceability.

Because our tubes are widely used in hydraulic systems, shipbuilding, and structural components, we’ve learned that early alignment between tube specification and end-use conditions can eliminate costly redesigns later. Certified to ISO 9001, ISO 14001, CE, and RoHS, we aim to be more than a supplier—we position ourselves as a long-term technical partner, occasionally sharing process suggestions that help customers optimize their cylinder assemblies.

With annual output exceeding 50,000 tons and fully integrated manufacturing—from cutting and chamfering to surface treatment—we continue investing in automation and smart systems to support global clients who rely on stable, repeatable Pneumatic Cylinder Tube performance.

English

English Español

Español русский

русский