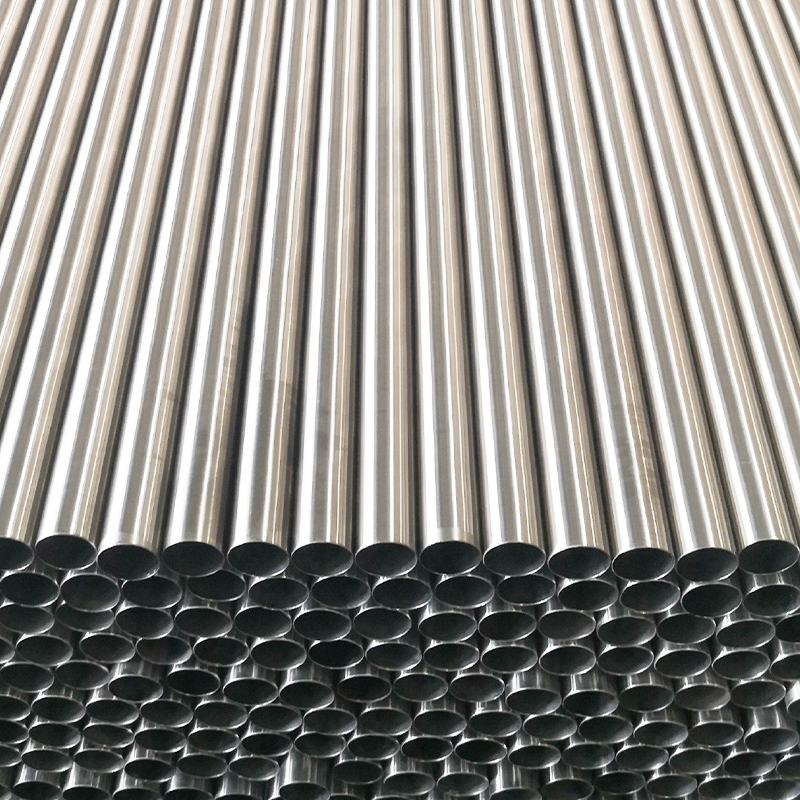

Our Chrome-Plated ID Pneumatic Cylinder Tubes feature a high-strength carbon steel body with a precision chrome-plated inner diameter (ID). These tubes are engineered for smooth piston operation, long service life, and excellent wear resistance.Ideal for industrial and automation applications, these tubes provide high durability at a competitive cost and are commonly used in hydraulic and pneumatic cylinders.

Typical Steel Grades

· 45# Carbon Steel – medium-duty applications with good machinability and strength

· 4130 Alloy Steel – higher toughness and fatigue resistance for demanding applications

Other steel grades available upon request for specific mechanical or corrosion requirements.

Common Sizes (OD × WT × Length)

·Ø20 × 1.5 mm × 2500 mm

·Ø25 × 1.5 mm × 2500 mm

·Ø32 × 2 mm × 2500 mm

·Ø40 × 2 mm × 2500 mm

·Ø50 × 2.5 mm × 2500 mm

·Ø63 × 2.5 mm × 2500 mm

·Ø76 × 3 mm × 2500 mm

·Ø89 × 3 mm × 2500 mm

·Ø101 × 3 mm × 2500 mm

·Ø114 × 3.5 mm × 2500 mm

·Ø127 × 4 mm × 2500 mm

·Ø140 × 4 mm × 2500 mm

·Ø159 × 4 mm × 2500 mm

·Ø168 × 4 mm × 2500 mm

·Ø194 × 5 mm × 2500 mm

·Ø200 × 5 mm × 2500 mm

·Ø219 × 5 mm × 2500 mm

·Ø250 × 6 mm × 2500 mm

Custom diameters, wall thicknesses, and lengths available upon request.

Technical Specifications

·Material: Carbon Steel (45# / 4130)

·Surface Finish: Chrome-plated ID, Ra ≤ 0.2 μm

·Tolerance: H8 or tighter on request

·Straightness: ≤ 0.3 mm/m

·Roundness: ≤ 0.03 mm

·Application: Pneumatic cylinder tubes with precision ID

Manufacturing Process

1. Steel Tube Selection – high-quality carbon steel 45# or 4130

2. Cold Drawing – improves dimensional accuracy and surface finish

3. ID Chrome Plating – enhances wear resistance and reduces friction

4. Grinding & Polishing – ensures mirror-like ID and H8 tolerance

5. Cut-to-Length and End Finishing – precise lengths and chamfers

6. Inspection – straightness, roundness, dimensional accuracy, and surface finish

Key Features & Benefits

·Precision chrome-plated ID for smooth piston travel

·High wear resistance due to chrome plating and carbon steel body

·High dimensional precision (H8 tolerance)

·Available in metric and imperial sizes

·Cost-effective solution for industrial and automation applications

Applications

·Pneumatic cylinders in automation and robotics

·Industrial machinery and presses

·Medium-duty hydraulic cylinders

·Mobile machinery and lifting equipment

·General industrial pneumatic applications

English

English Español

Español русский

русский