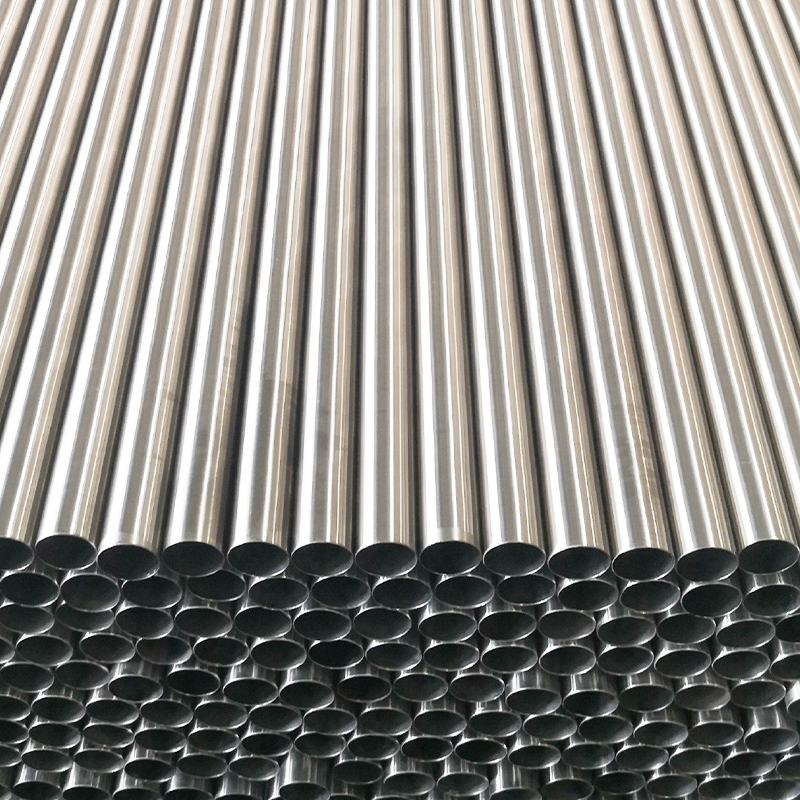

Our Stainless Steel Pneumatic Cylinder Tubes are precision-manufactured from 304 or 316 stainless steel and feature a polished inner diameter (ID) to ensure smooth piston movement, corrosion resistance, and long service life.These tubes are ideal for corrosive environments, including food processing, chemical, marine, and offshore applications, where stainless steel is required for reliability and hygiene.

Typical Steel Grades

·304 Stainless Steel – excellent corrosion resistance, general-purpose applications

·316 Stainless Steel – superior corrosion resistance, particularly against chlorides and aggressive chemicals

Custom grades available on request for specialized applications.

Common Sizes (OD × ID × WT × Length)

|

OD (mm)

|

ID (mm)

|

Wall Thickness (mm)

|

Length (mm)

|

|

11.18

|

10

|

0.6

|

2500

|

|

13.4

|

12

|

0.7

|

2500

|

|

17.4

|

16

|

0.7

|

2500

|

|

21.4

|

20

|

0.7

|

2500

|

|

26.4

|

25

|

0.7

|

2500

|

|

33.6

|

32

|

0.8

|

2500

|

|

41.6

|

40

|

0.8

|

2500

|

|

52

|

50

|

1

|

2500

|

|

65

|

63

|

1.2

|

2500

|

|

76

|

74

|

1.5

|

2500

|

|

89

|

85

|

2

|

2500

|

|

101

|

95

|

2.2

|

2500

|

|

114

|

107

|

2.5

|

2500

|

|

127

|

120

|

2.8

|

2500

|

|

140

|

132

|

3

|

2500

|

|

159

|

150

|

3.5

|

2500

|

|

168

|

159

|

3.5

|

2500

|

|

194

|

183

|

4

|

2500

|

|

200

|

189

|

4

|

2500

|

|

219

|

208

|

4.5

|

2500

|

Custom diameters, wall thicknesses, and lengths are also available upon request.

Technical Specifications

·Material: Stainless Steel 304 / 316

·Surface Finish: Polished ID for low friction

·Tolerance: H8 or tighter upon request

·Straightness: ≤ 0.3 mm/m

·Roundness: ≤ 0.03 mm

·Application: Pneumatic cylinders in corrosive or high-precision environments

Manufacturing Process

1. Stainless Steel Tube Selection – 304 or 316 quality

2. Cold Drawing / Polishing – improves dimensional accuracy and surface finish

3. ID Polishing / Honing – ensures Ra ≤ 0.4 μm for smooth piston operation

4. Cut-to-Length and End Finishing – precise lengths and chamfers as required

5. Inspection – straightness, roundness, dimensional accuracy, and surface finish

Key Features & Benefits

·Corrosion-resistant stainless steel – 304 or 316

·Polished ID – reduces friction and improves cylinder seal life

·High dimensional precision – H8 tolerance

·Custom sizes available – metric and imperial

·Ideal for food, chemical, marine, and offshore applications

Applications

· Pneumatic cylinders in food and beverage processing

· Chemical and pharmaceutical machinery

· Marine and offshore hydraulic/pneumatic systems

· Automation and robotics requiring corrosion resistance

· Any environment requiring smooth, polished stainless steel tubing

English

English Español

Español русский

русский