Heat exchanger tubes play a vital role in optimizing thermal processes in various industrial systems. These tubes are integral components in systems where heat needs to be transferred efficiently between two different fluids or gases. In industries like power generation, automotive, and chemical processing, the applications of heat exchanger tubes are highly specialized to meet specific operational requirements. For example, in power plants, heat exchanger tubes are utilized to transfer heat from the hot exhaust gases to water, turning it into steam for turbines. The efficiency of these tubes directly impacts the overall performance of the system.

Heat Exchanger Tubes in Power Plants

In power plants, heat exchanger tubes are primarily used in condensers and cooling systems. The main role is to cool steam that passes through the system, converting it back into water for reuse. These tubes must withstand high pressures and temperatures while providing a reliable heat transfer mechanism. The design of the heat exchanger tubes, including the materials used, must be suitable for long-term use in a harsh environment that involves constant thermal cycling and exposure to chemicals.

Impact of Material Selection on Performance

The performance of heat exchanger tubes depends largely on the material chosen for manufacturing. Common materials include copper, aluminum, stainless steel, and titanium. Each material has its own benefits and is chosen based on the specific application, temperature range, and fluid type. For instance, copper tubes are highly efficient in heat transfer but are more prone to corrosion compared to stainless steel. Stainless steel tubes, on the other hand, offer greater resistance to corrosion and high-temperature conditions, making them ideal for the oil & gas industry.

Innovations in Heat Exchanger Tube Manufacturing

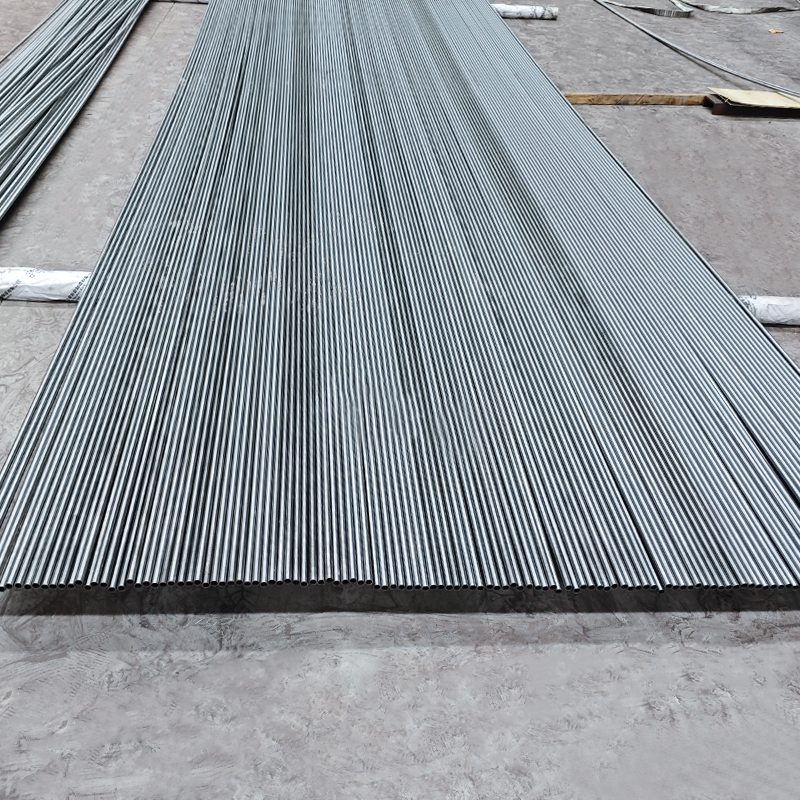

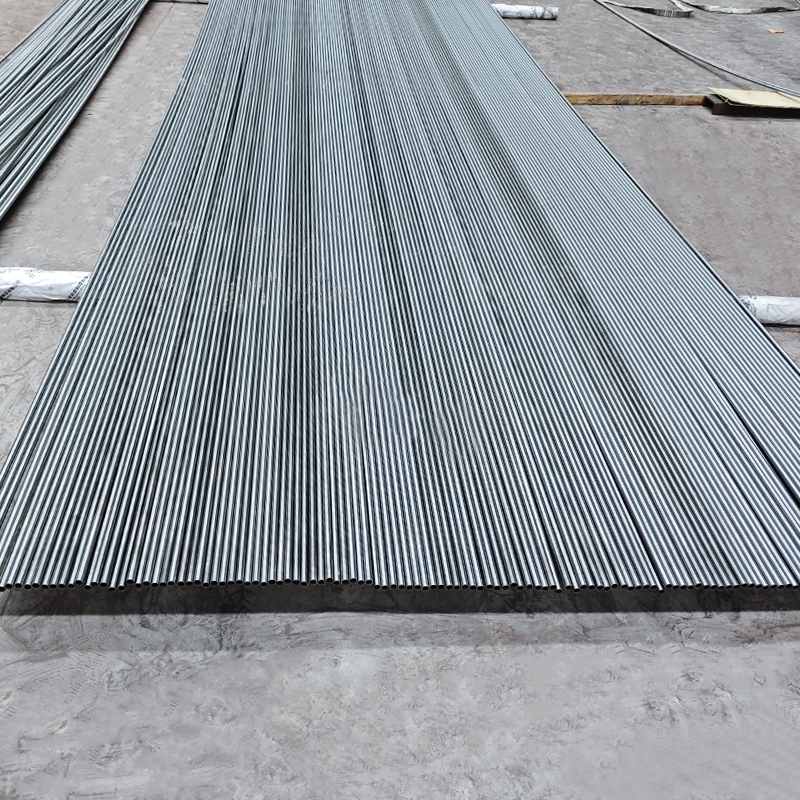

The manufacturing of heat exchanger tubes has evolved significantly over the years, thanks to technological advancements. Traditional methods such as extruding and bending have been complemented by more advanced techniques like cold drawing and laser welding, allowing manufacturers to produce tubes with higher precision and durability. These innovations have enhanced the overall heat transfer efficiency and reliability of the tubes, enabling them to perform better under extreme conditions.

Cold Drawing Process

Cold drawing is a widely used technique in manufacturing heat exchanger tubes. It involves pulling the tube material through a die to reduce its diameter and increase its length. This process improves the mechanical properties of the tubes, such as tensile strength and surface finish. Cold-drawn tubes also have better dimensional accuracy, making them ideal for applications that require precise fitment and enhanced thermal efficiency.

Smart Manufacturing Systems

Advances in automation and smart manufacturing systems have revolutionized the production of heat exchanger tubes. These systems enable real-time monitoring of various production parameters, such as temperature, pressure, and dimensional accuracy. They help reduce errors, improve production speeds, and ensure the consistent quality of the tubes. By integrating these technologies, manufacturers can achieve flexible, high-mix, low-volume production while maintaining high standards of quality control.

When selecting heat exchanger tubes for a specific application, several factors must be considered to ensure optimal performance and longevity. These factors include material selection, tube size, corrosion resistance, and heat transfer capabilities. Below is a brief overview of these considerations:

- Material: The material must be chosen based on its ability to withstand the operating environment, including temperature, pressure, and exposure to chemicals.

- Tube Size: The diameter and length of the tube should match the design specifications of the heat exchanger system to ensure efficient heat transfer.

- Corrosion Resistance: Tubes must be resistant to corrosion, especially in industries like oil & gas and chemical processing, where fluids may contain corrosive substances.

- Heat Transfer Efficiency: The design and surface area of the tube should maximize heat exchange to ensure the system operates efficiently and reduces energy consumption.

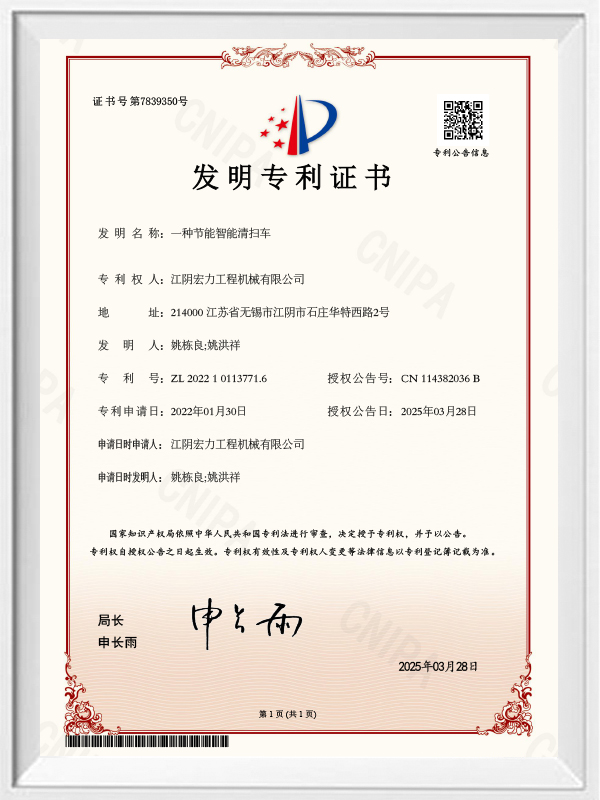

Global Standards for Heat Exchanger Tubes

Heat exchanger tubes must meet certain global standards to ensure they are safe, reliable, and effective for use in various industrial applications. Certifications such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and CE certification help ensure that the tubes are manufactured according to international quality standards. These standards also promote sustainability by encouraging manufacturers to reduce waste and environmental impact during production.

Industry-Specific Certifications

Different industries require heat exchanger tubes to meet specific standards to ensure safety and reliability. For example, the oil and gas sector often requires tubes to be certified to API (American Petroleum Institute) standards to ensure they can handle high pressures and temperatures. Similarly, the automotive industry may require tubes to meet SAE (Society of Automotive Engineers) standards to ensure compatibility with engine cooling systems.

English

English Español

Español русский

русский