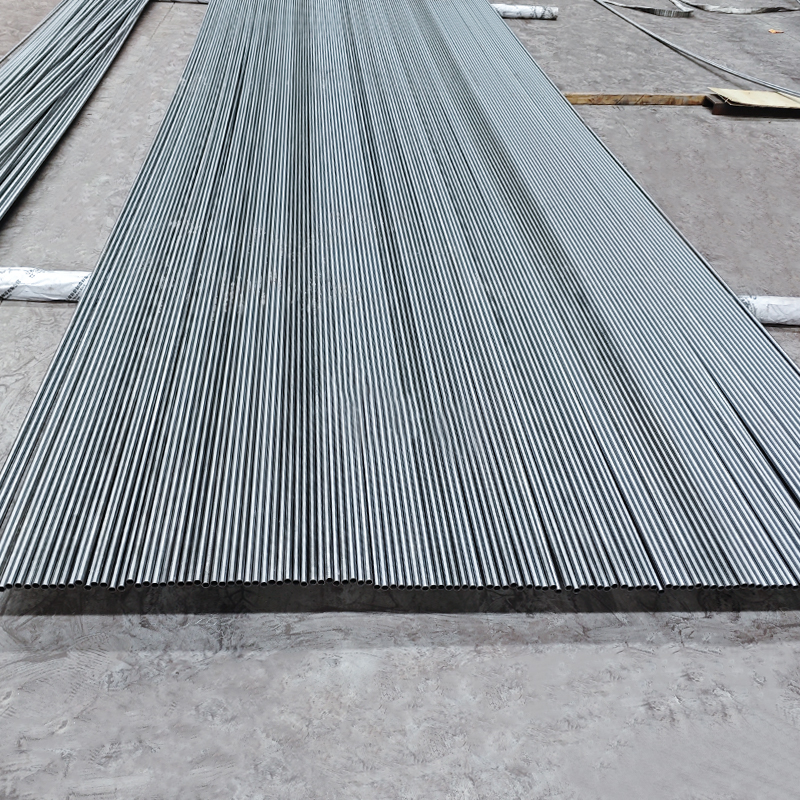

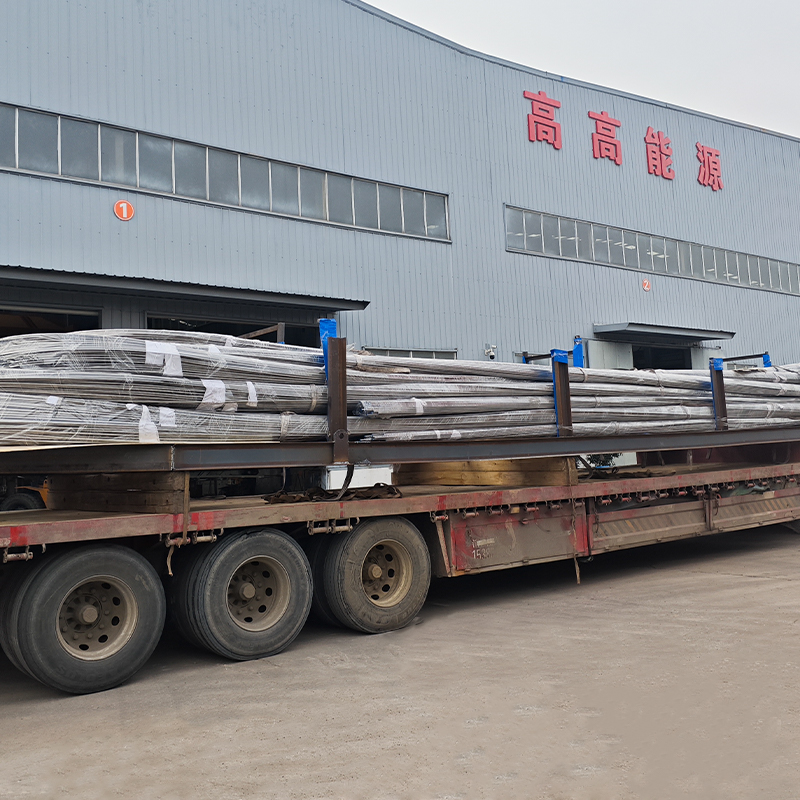

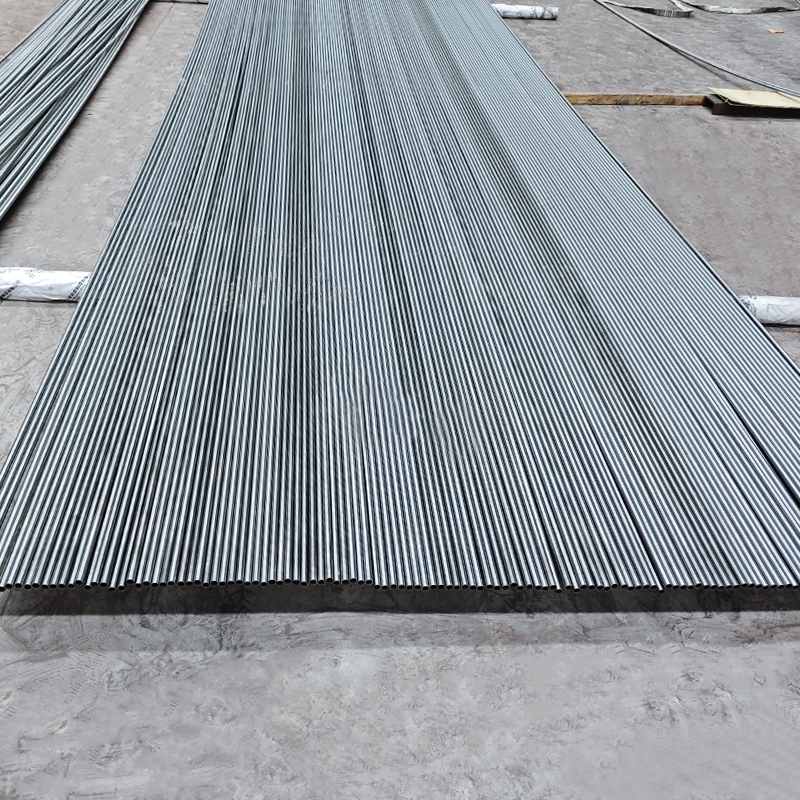

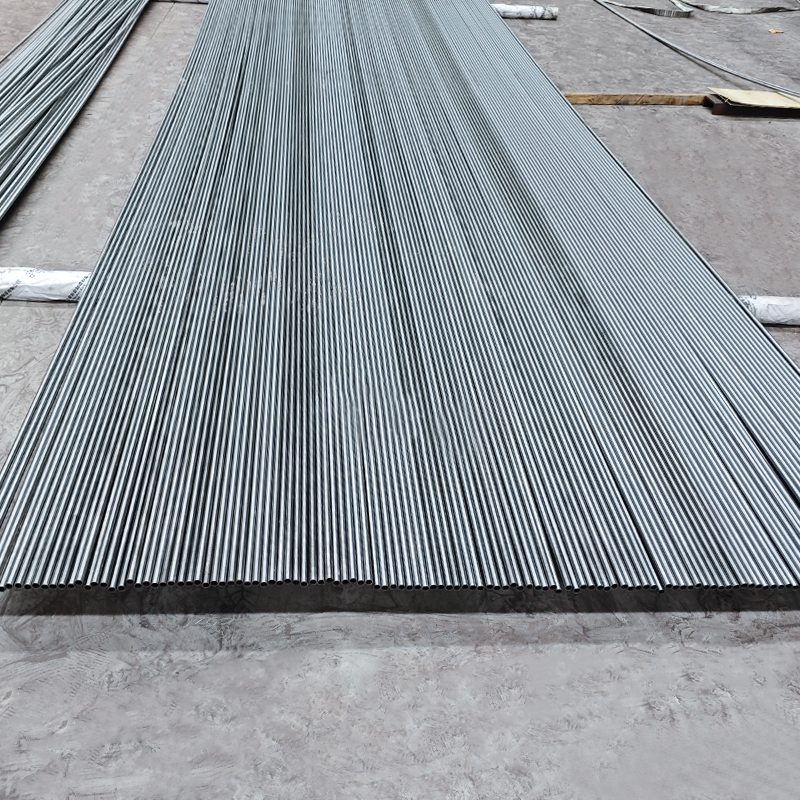

Our Carbon Steel Heat Exchanger Tubes are designed for use in low- to medium-temperature heat transfer applications, such as condensers, boilers, and economizers.

They are manufactured to ASTM, EN, and DIN standards, ensuring excellent thermal conductivity, mechanical strength, and dimensional precision. Both seamless and welded options are available to suit different project requirements.

Key Features

·High thermal conductivity and heat transfer efficiency

·Suitable for low- and medium-temperature service

·Seamless & welded tube manufacturing available

·Conforming to ASTM, EN, DIN international standards

·Excellent straightness and dimensional control

Technical Specifications

|

Parameter

|

Specification

|

|

Standards

|

ASTM A179 / A192, EN 10216-1, DIN 17175

|

|

Typical Grades

|

SA179, SA192, ST35.8, ST45.8, P235TR1

|

|

OD (Outside Diameter)

|

12.7 – 101.6 mm

|

|

Wall Thickness (WT)

|

1.2 – 10 mm

|

|

Length

|

Up to 12 m (cut-to-length available)

|

|

Manufacturing Process

|

Seamless (hot finished / cold drawn), Welded (ERW)

|

|

Heat Treatment

|

Annealed, Normalized, Stress Relieved

|

|

Surface Finish

|

Pickled, Oiled, Polished

|

Common Sizes

·Ø19.05 mm x 2.11 mm (3/4 in x 0.083 in)

·Ø25.4 mm x 2.77 mm (1 in x 0.109 in)

·Ø38.1 mm x 3.2 mm (1.5 in x 0.125 in)

·Ø50.8 mm x 3.68 mm (2 in x 0.145 in)

·Ø63.5 mm x 4 mm (2.5 in x 0.157 in)

(Custom sizes available)

Manufacturing Process

1. Raw material selection – high-quality carbon steel billets/strips

2. Tube formation – seamless piercing & elongation or ERW welding

3. Cold drawing for precision (if required)

4. Heat treatment – annealed / normalized for ductility

5. Surface finishing – pickling, polishing, oiling

6. Testing – dimensional, hydrostatic, NDT (UT/ET)

Applications

·Boilers & Economizers

·Condensers & Heat Exchangers

·Industrial Process Cooling

·Refinery & Petrochemical Units

·Low to Medium Temperature Service

English

English Español

Español русский

русский