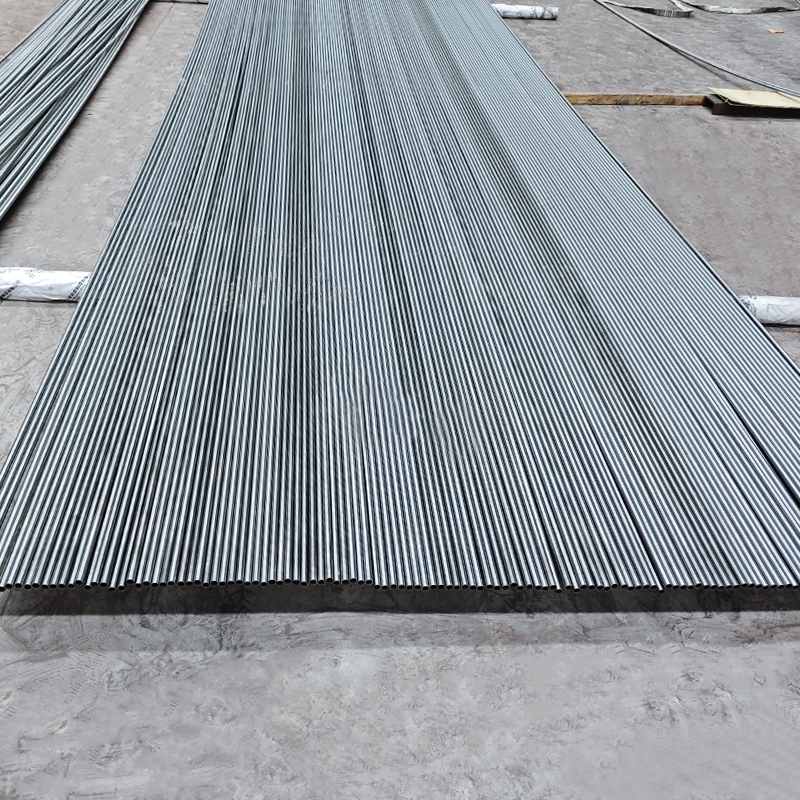

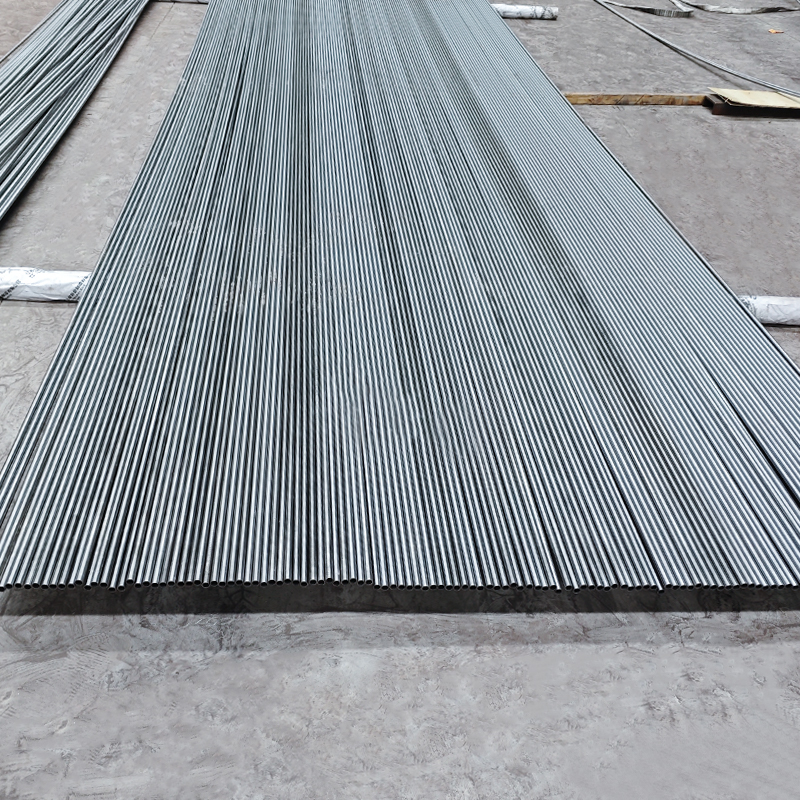

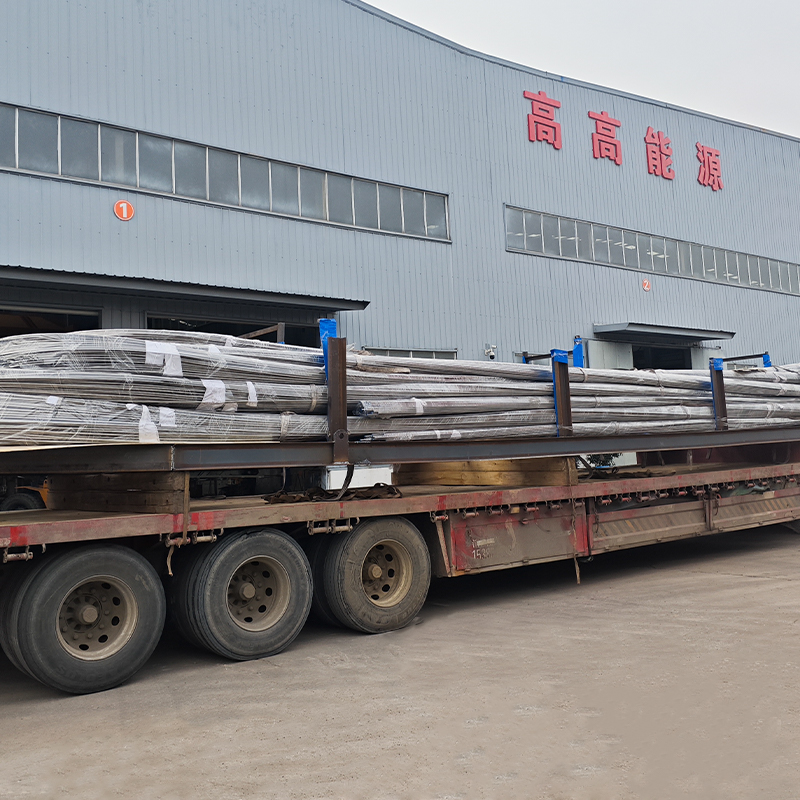

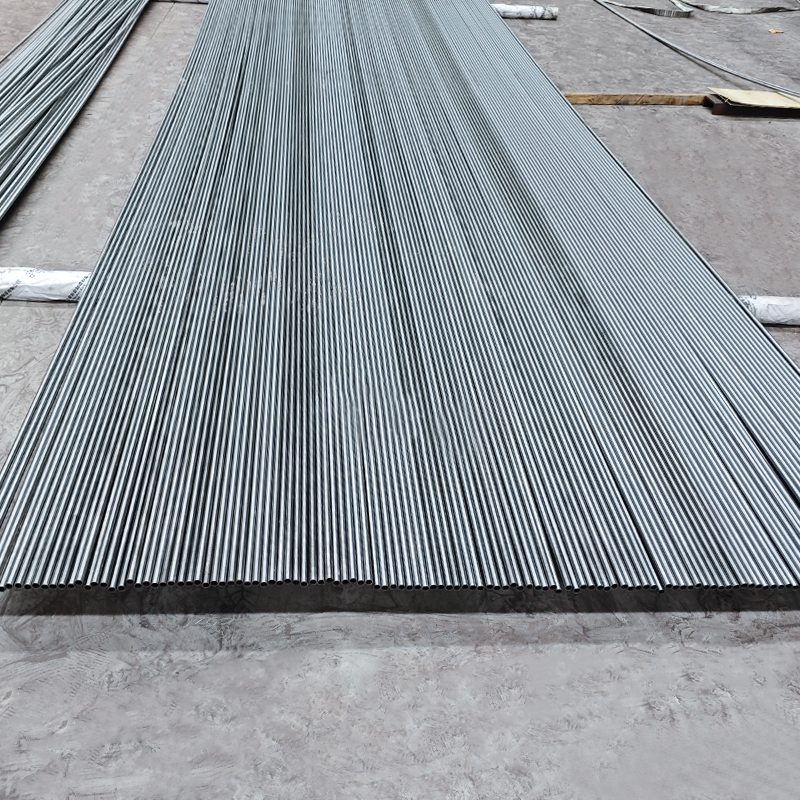

Our Stainless Steel Heat Exchanger Tubes are engineered for applications requiring high corrosion resistance, durability, and long service life.

They are widely used in chemical plants, desalination units, marine environments, and power generation where carbon steel is not suitable.

Available in seamless (cold drawn) and welded (ERW / TIG welded) forms, these tubes comply with international standards for heat exchangers, boilers, and condensers.

Key Features

·Exceptional corrosion resistance in harsh environments

·Available in seamless and welded executions

·High strength at both ambient and elevated temperatures

·Complies with ASTM, EN, DIN standards

·Long service life with reduced maintenance costs

Technical Specifications

|

Parameter

|

Specification

|

|

Standards

|

ASTM A213 / A249, EN 10216-5, DIN 17456

|

|

Typical Grades

|

304, 304L, 316, 316L, 321, 347

|

|

OD (Outside Diameter)

|

12.7 – 101.6 mm

|

|

Wall Thickness (WT)

|

1 – 6 mm

|

|

Length

|

Up to 12 m (cut-to-length available)

|

|

Manufacturing Process

|

Seamless (cold drawn), Welded (ERW/TIG)

|

|

Heat Treatment

|

Solution Annealed, Pickled, Passivated

|

|

Surface Finish

|

Bright Annealed, Polished, Pickled

|

Common Sizes

·Ø19.05 mm x 2.11 mm (3/4 in x 0.083 in)

·Ø25.4 mm x 2.11 mm (1 in x 0.083 in)

·Ø31.8 mm x 2.77 mm (1.25 in x 0.109 in)

·Ø38.1 mm x 2.77 mm (1.5 in x 0.109 in)

·Ø50.8 mm x 3.68 mm (2 in x 0.145 in)

(Customized OD / WT available)

Manufacturing Process

1. Raw material – stainless steel billets or hot rolled strips

2. Tube formation – seamless extrusion / welded (ERW / TIG)

3. Cold drawing for dimensional accuracy

4. Heat treatment – solution annealing for corrosion resistance

5. Surface finishing – bright annealed, polished, or pickled

6. Inspection – hydrostatic, Eddy Current, UT, mechanical testing

Applications

·Chemical Processing Plants

·Desalination & Marine Applications

·Food & Beverage Industry

·Power Generation – Condensers & Heat Exchangers

·Pharmaceutical & Clean Environments

English

English Español

Español русский

русский