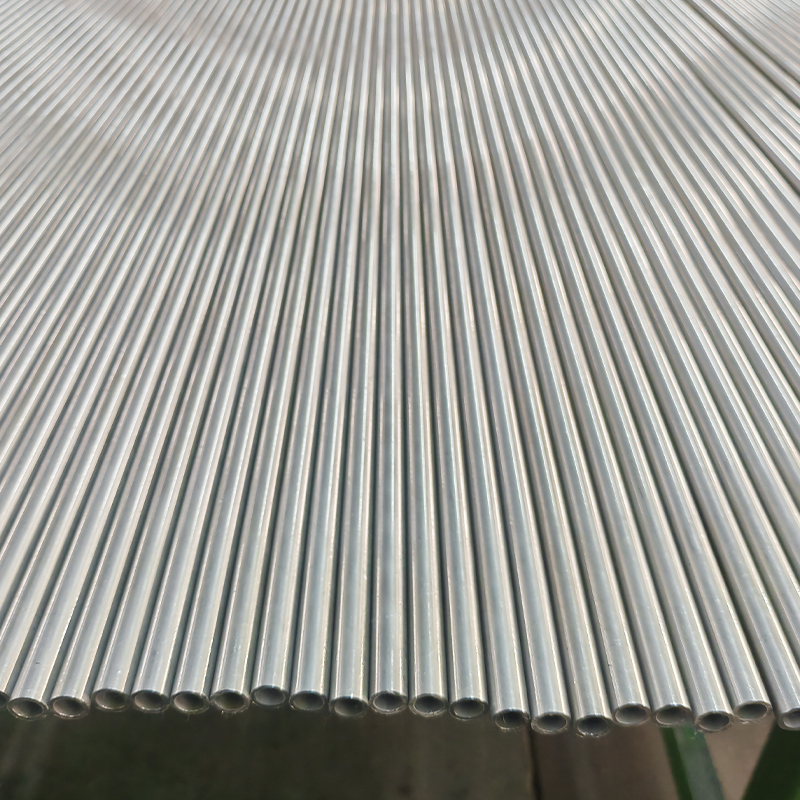

Our Honed and Skived & Roller Burnished (SRB) Tubes are manufactured from EN 10305-1 E355 cold drawn seamless steel tubes and precision processed to achieve exceptional surface smoothness (Ra ≤ 0.4 μm) and tight tolerance (H8).With a mirror-like internal bore finish, these tubes are specifically designed for use as hydraulic cylinder barrels, where low friction, long seal life, and high wear resistance are essential.

Typical Steel Grades

· EN 10305-1 E355 (standard)

· ST52.3 (DIN equivalent)

· 20MnV6 (alternative grade for machining)

· ASTM A519 1020 / 1026 (optional)

Common Sizes (OD × WT × ID)

·Ø40 mm × 5 mm (ID Ø30 mm)

·Ø63.5 mm × 6 mm (ID Ø51.5 mm)

·Ø90 mm × 8 mm (ID Ø74 mm)

·Ø100 mm × 10 mm (ID Ø80 mm)

·Ø125 mm × 12.5 mm (ID Ø100 mm)

·Ø150 mm × 15 mm (ID Ø120 mm)

Imperial sizes (inch-based) also available upon request.

Technical Specifications

·Standard: EN 10305-1, ISO H8 tolerance

·Condition: Cold Drawn + Honed or SRB

·Bore Tolerance: H8 (or tighter upon request)

·Surface Roughness: Ra ≤ 0.4 μm (honed) / Ra ≤ 0.2 μm (SRB)

·Straightness: ≤ 0.3 mm/m

·Roundness: ≤ 0.03 mm

Manufacturing Process

1. Cold Drawn Seamless Tube (E355) production

2. Heat Treatment (Normalization / Stress Relief)

3. Rough Boring (if required)

4. Honing → controlled abrasive finish for Ra ≤ 0.4 μm

5. Skiving & Roller Burnishing (optional alternative) → mirror ID finish Ra ≤ 0.2 μm

6. Final Inspection → roundness, straightness, tolerance, roughness checks

Key Features & Benefits

·Ready-to-assemble cylinder barrel → saves machining time

·Ultra-smooth bore finish → longer seal and piston life

·Excellent dimensional accuracy (H8) → ideal for hydraulic cylinders

·Available in both honed and SRB finishes

·Reduces maintenance costs by minimizing wear

Applications

·Hydraulic cylinder barrels (construction machinery, agricultural equipment)

·Pneumatic cylinders

·Heavy-duty lifting systems

·Press machines and industrial hydraulics

English

English Español

Español русский

русский