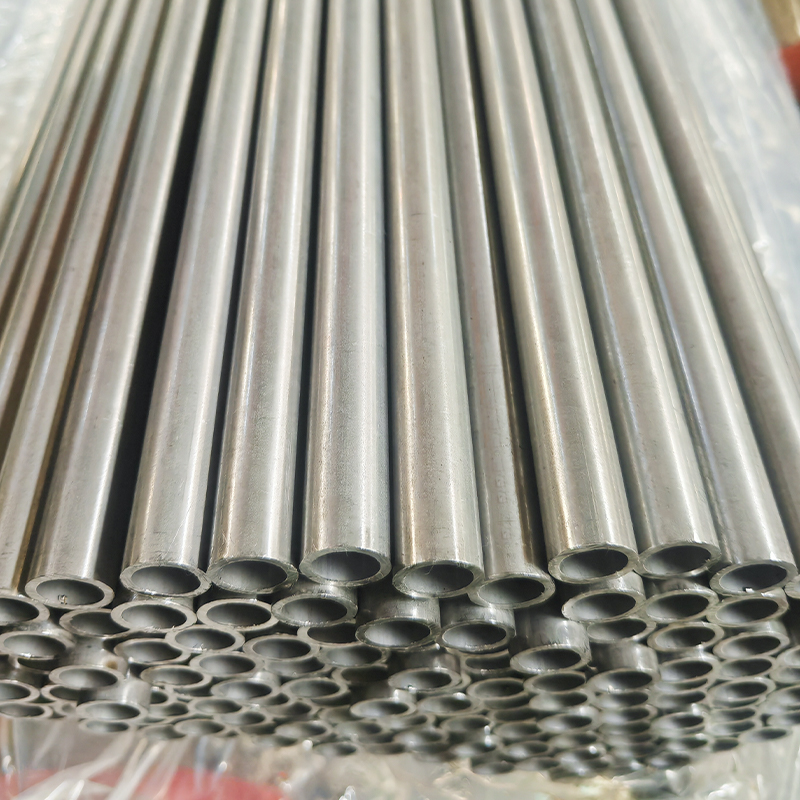

Our Honed and Skived & Roller Burnished (SRB) Tubes – ASTM A519 are precision cold drawn seamless (CDS) steel pipes processed to achieve a mirror-like inner diameter finish. With tolerances up to H8 and surface roughness as low as Ra 0.4 μm, these tubes are ideal for hydraulic cylinder barrels requiring low friction, long seal life, and high wear resistance.

Designed for North American and international markets that follow ASTM standards, these tubes are widely used in construction, industrial, agricultural, and automotive hydraulic systems.

Typical Steel Grades

·ST52 – good mechanical strength, machinability, and weldability

·20MnV6 – micro-alloyed steel for high wear resistance and toughness

·27SiMn – high-strength alloy steel for heavy-duty hydraulic cylinders

·Other grades available upon request (ASTM A519 1020, 1026, DOM)

Common Sizes (OD × WT × ID)

·Ø40 mm × 5 mm (ID Ø30 mm)

·Ø63.5 mm × 6 mm (ID Ø51.5 mm)

·Ø90 mm × 8 mm (ID Ø74 mm)

·Ø100 mm × 10 mm (ID Ø80 mm)

·Ø125 mm × 12.5 mm (ID Ø100 mm)

·Ø150 mm × 15 mm (ID Ø120 mm)

Imperial sizes (inch-based DOM tubing) are available upon request.

Technical Specifications

·Standard: ASTM A519 Type 5 / DOM tubing

·Condition: Cold Drawn Seamless, Honed or SRB

·ID Tolerance: H8 (or tighter on request)

·Surface Finish: Ra ≤ 0.4 μm (honed), Ra ≤ 0.2 μm (SRB)

·Straightness: ≤ 0.3 mm/m

·Roundness: ≤ 0.03 mm

Manufacturing Process

1. ASTM A519 Seamless Tube Production – piercing and hot rolling

2. Cold Drawing Over Mandrel (DOM) – improves dimensional accuracy and mechanical properties

3. Heat Treatment / Normalization – ensures internal structure stability

4. Honing – precise abrasive finish to achieve smooth ID

5. Skiving & Roller Burnishing (SRB) – optional mirror finish for ultra-low Ra

6. Inspection – dimensional, straightness, roundness, and surface finish checks

Key Features & Benefits

·Ultra-smooth ID for long-lasting seals and pistons

·High dimensional accuracy (H8) for reliable cylinder assembly

·Available in both honed and SRB finishes

·Cost-effective solution for medium- to high-pressure hydraulic cylinders

·Compatible with metric and imperial standards

Applications

· Hydraulic cylinders in construction, agriculture, and industrial machinery

· Pneumatic cylinder barrels

· Heavy-duty lifting equipment

· Press machines and industrial automation

English

English Español

Español русский

русский