Dimensional Stability Requirements for Shock Absorber Reservoir Tubes

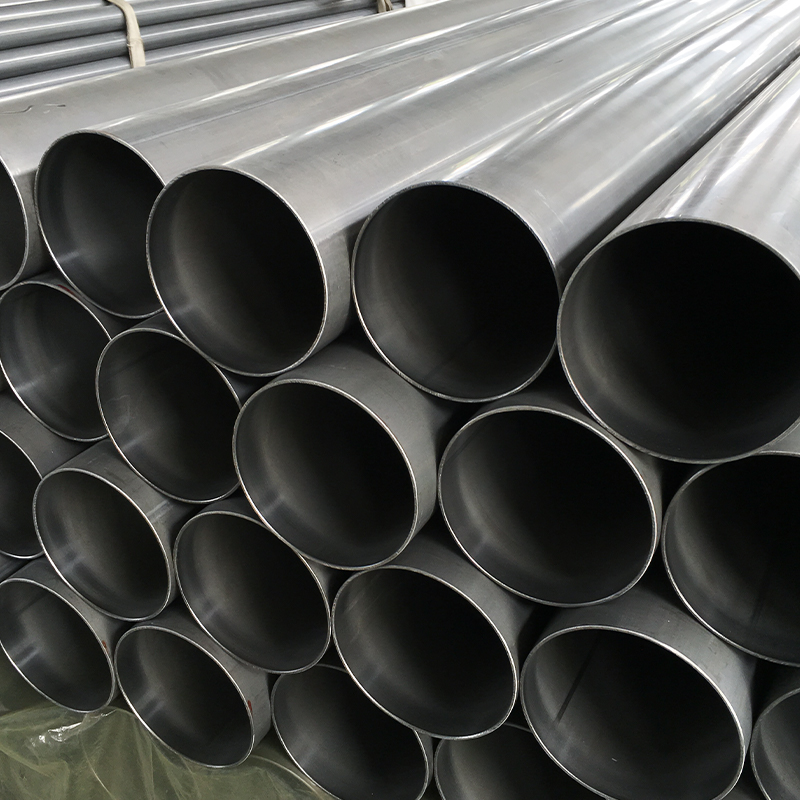

Precision steel tubes for shock absorber reservoirs are subjected to continuous internal pressure fluctuations and temperature changes during vehicle operation. Any deviation in inner diameter, roundness, or wall thickness directly affects oil volume stability and damping consistency. For this reason, reservoir tubes demand far tighter dimensional control than ordinary mechanical tubing.

Jiangsu Suao Metal Product Co., Ltd. specializes in high-precision cold drawn steel tubes, making dimensional stability a core manufacturing focus. With integrated cold drawing, straightening, and finishing lines, Suao ensures that reservoir tubes maintain consistent geometry throughout their full length, supporting reliable shock absorber performance in long-term service.

Key Dimensional Factors Affecting Reservoir Performance

- Inner Diameter Tolerance: Precise inner diameter ensures stable oil flow and predictable pressure response.

- Wall Thickness Uniformity: Consistent wall thickness prevents localized deformation under pressure.

- Roundness Control: High roundness improves sealing efficiency between reservoir and internal components.

- Straightness Accuracy: Proper straightness simplifies assembly and reduces stress during welding or crimping.

Cold Drawn Tubes and Pressure Resistance in Reservoir Design

Cold drawn tubes for shock absorber reservoirs offer superior mechanical consistency compared to hot-rolled alternatives. The cold drawing process refines the steel grain structure, increases yield strength, and improves surface finish—key factors when tubes are exposed to repeated pressure cycles.

At Jiangsu Suao Metal Product Co., Ltd., cold drawing is combined with controlled heat treatment to balance strength and ductility. This approach allows reservoir tubes to withstand internal pressure without becoming overly brittle, reducing the risk of cracking during extreme driving conditions.

| Manufacturing Step |

Contribution to Reservoir Tube Performance |

| Cold Drawing |

Enhances dimensional accuracy and improves pressure-bearing capability. |

| Heat Treatment |

Relieves internal stress and stabilizes mechanical properties. |

| Straightening |

Ensures uniform alignment for downstream welding and assembly. |

Surface Quality and Cleanliness for Hydraulic Compatibility

Shock absorber reservoirs are directly exposed to hydraulic oil, making internal surface quality a critical factor. Surface defects or contamination can accelerate oil degradation and increase wear on internal components. Therefore, reservoir tubes require controlled surface roughness and strict cleanliness standards.

Jiangsu Suao Metal Product Co., Ltd. integrates finishing and surface treatment into its production workflow, allowing reservoir tubes to meet hydraulic system cleanliness expectations. These capabilities support stable damping behavior and reduce the risk of premature shock absorber failure.

Common Surface Treatment Approaches for Reservoir Tubes

- Pickled and Oiled Finish: Removes surface scale while providing temporary corrosion protection.

- Phosphated Surface: Improves corrosion resistance and coating adhesion.

- Clean Honed Surface: Reduces friction and supports stable oil flow inside the reservoir.

Production Scale and Quality Consistency for Automotive Supply Chains

Shock absorber manufacturers require consistent tube quality across large production volumes to maintain uniform vehicle performance. Variations between batches can lead to damping imbalance and increased quality risks during assembly.

With two production facilities covering over 36,000 square meters, more than 200 employees, and an annual output exceeding 50,000 tons, Jiangsu Suao Metal Product Co., Ltd. is structured to support stable, repeatable supply. Its integrated inspection and production systems help ensure that precision steel tubes for shock absorber reservoirs meet consistent standards across global automotive and industrial markets.

English

English Español

Español русский

русский