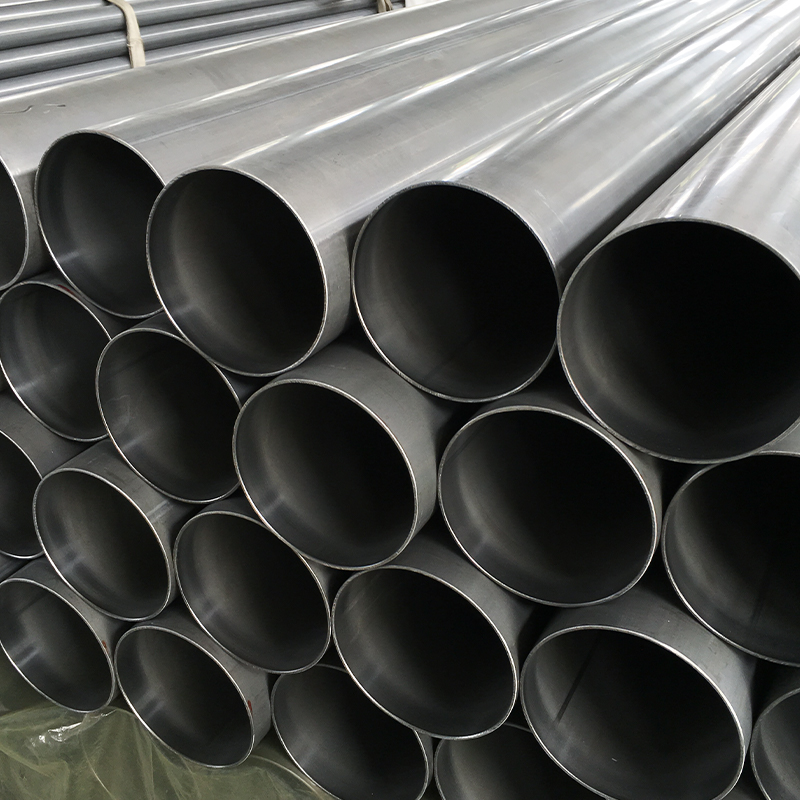

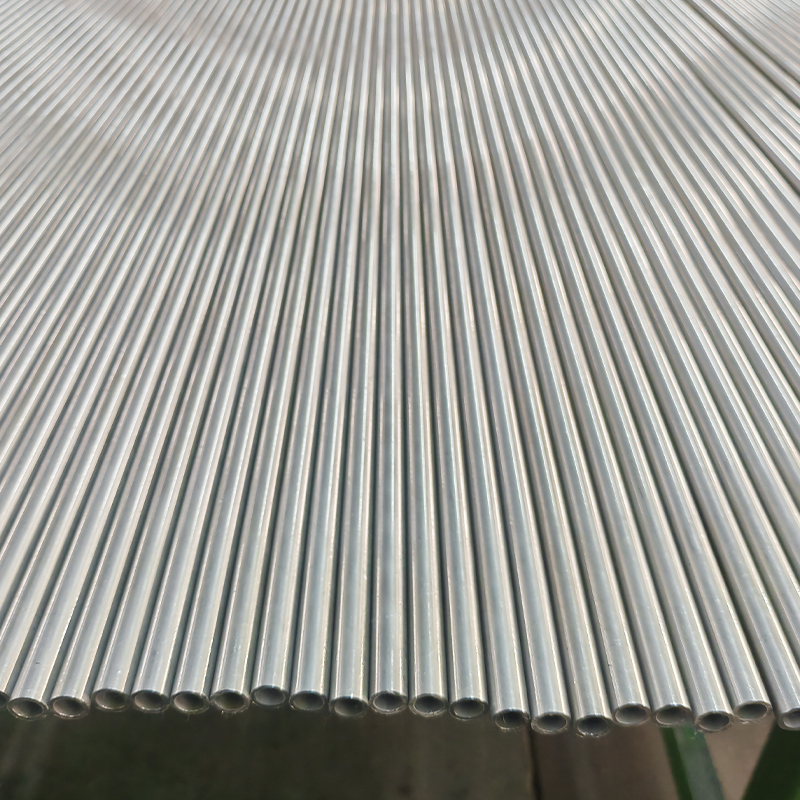

Our Seamless Shock Absorber Tubes are manufactured to EN 10305-1 using high-quality steels such as E235 and E355. With no weld seam, these tubes offer superior strength, fatigue resistance, and flawless surface finish, making them ideal for automotive shock absorbers, struts, and high-performance hydraulic dampers.

These precision tubes combine:

·High dimensional accuracy

·Excellent straightness & concentricity

·Smooth internal and external surfaces

·Enhanced fatigue strength for long service life

Key Features

·Standard: EN 10305-1 (Cold Drawn Seamless Precision Steel Tubes)

·Steel Grades: E235, E355, ST52.3, optional: 20MnV6, 25CrMo4

·Seamless construction → no weld seam, improved fatigue resistance

·Cold drawn process → refined dimensions & smooth surface

·High straightness → suitable for automated shock absorber assembly

·Excellent machinability → suitable for honing, plating, or coating

Technical Specifications

|

Parameter

|

Specification

|

|

Standard

|

EN 10305-1

|

|

Steel Grade Options

|

E235, E355, ST52.3, 20MnV6, 25CrMo4

|

|

OD Example

|

Ø40 mm (range: Ø20–Ø100 mm)

|

|

Wall Thickness (WT)

|

2 mm (range: 1–5 mm)

|

|

Manufacturing Process

|

Cold Drawn Seamless (CDS)

|

|

Surface Finish

|

Smooth, free from defects, plating-ready

|

|

Tolerances

|

As per EN 10305-1

|

|

Applications

|

Automotive shock absorbers, hydraulic dampers, suspension struts

|

Common Sizes Available

|

Outside Diameter (OD)

|

Wall Thickness (WT)

|

Steel Grades Available

|

|

Ø20–25 mm

|

1.5–2.5 mm

|

E235, E355, 20MnV6

|

|

Ø30–40 mm

|

1.5–3 mm

|

E235, ST52.3, E355

|

|

Ø50–60 mm

|

2–4 mm

|

E355, 20MnV6, 25CrMo4

|

|

Ø70–100 mm

|

2.5–5 mm

|

E355, ST52.3

|

Manufacturing Process

1. Billet Piercing & Hot Rolling – Produces seamless hollows without weld seam

2. Cold Drawing – Refines dimensions, straightness & concentricity

3. Heat Treatment (Normalizing / Stress Relieving) – Consistent mechanical properties

4. Surface Finishing – Grinding, polishing, or phosphating as required

5. Quality Control – Dimensional inspection, ultrasonic & eddy current testing, straightness check

Advantages of Our Seamless Shock Absorber Tubes

·No weld seam → superior fatigue strength

·High precision → stable performance in dynamic suspension systems

·Smooth bore & OD → ideal for sealing systems and plating

·Enhanced durability in heavy-duty automotive & industrial applications

·Custom lengths & finishes available

Applications

·Passenger car shock absorbers

·Motorcycle suspension systems

·Heavy truck & bus suspension dampers

·High-performance hydraulic struts

·Industrial vibration dampers

English

English Español

Español русский

русский