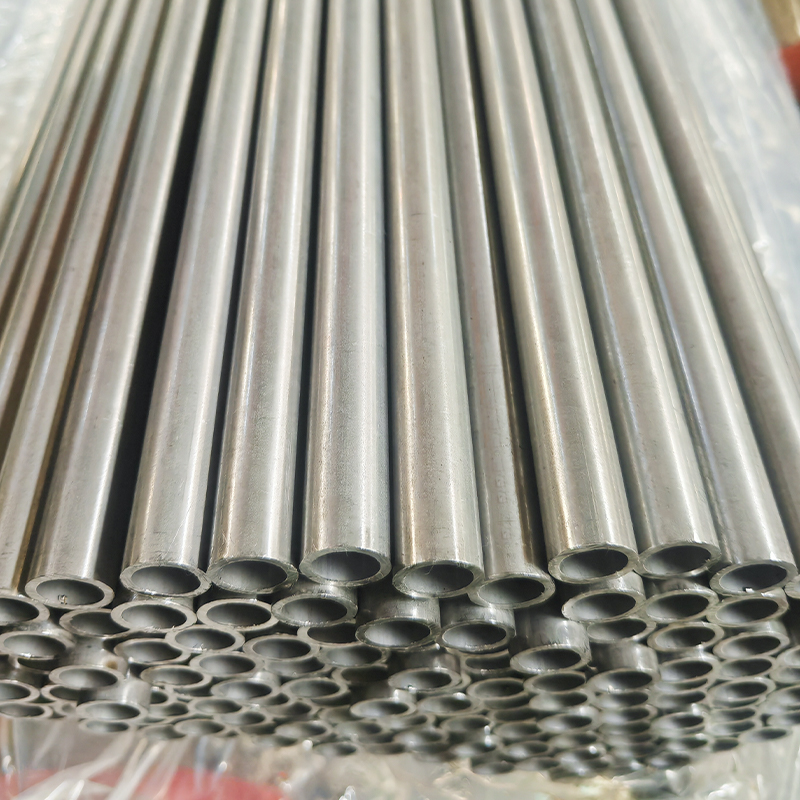

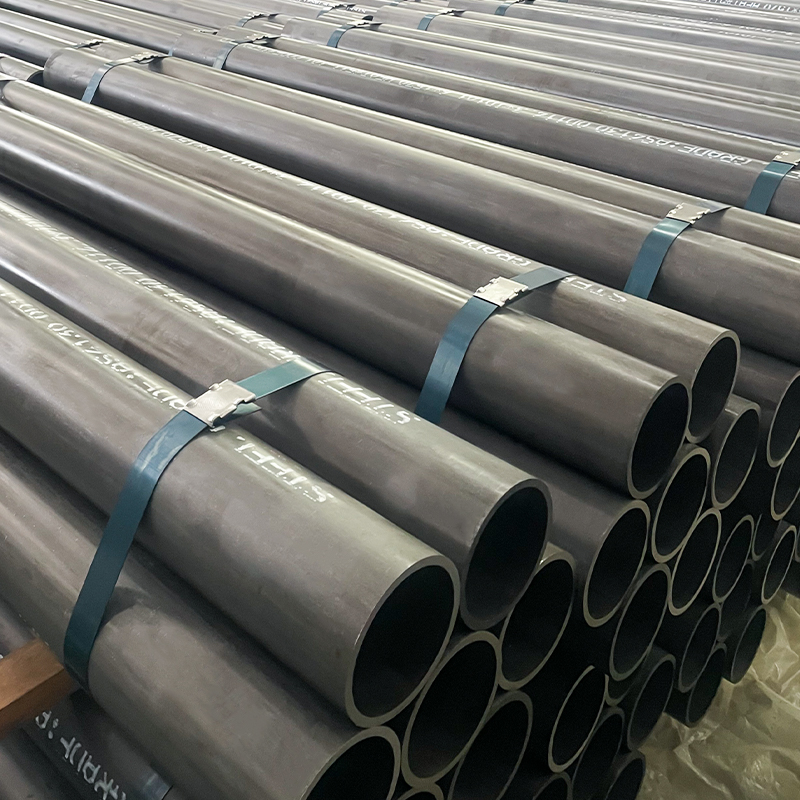

Our ASTM A519 Hydraulic Cylinder Tubes are precision-manufactured using cold drawn seamless (CDS) steel pipes, ensuring superior mechanical strength, dimensional accuracy, and smooth inner surfaces.Produced in grades ST52, 27SiMn, and 20MnV6, these tubes are specially developed for hydraulic cylinder manufacturing, where high pressure, reliability, and excellent machinability are required.Compared with welded tubes, seamless tubes (ASTM A519) deliver higher strength, better fatigue resistance, and longer service life — making them the first choice for heavy-duty hydraulic applications.

Key Features

· Standard: ASTM A519

· Steel Grades: ST52, 27SiMn, 20MnV6

· Process: Cold Drawn Seamless (CDS)

· Designed for honing or SRB finishing

· Excellent straightness & roundness

· High mechanical strength for high-pressure systems

Technical Specifications

|

Parameter

|

Specification

|

|

Standard

|

ASTM A519

|

|

Steel Grades

|

ST52, 27SiMn, 20MnV6

|

|

Outer Diameter (OD)

|

Ø30 – Ø500 mm (custom sizes on request)

|

|

Wall Thickness (WT)

|

2 – 50 mm

|

|

Length

|

Up to 12 m, cut-to-length available

|

|

Tolerances

|

H9 – H11 (on request)

|

|

Surface Condition

|

As drawn / ready for honing or SRB

|

Manufacturing Process

1. Seamless tube production from billet (piercing & hot rolling)

2. Cold drawing for improved dimensions, surface finish, and strength

3. Heat treatment (normalized, quenched & tempered if required)

4. Straightening for excellent linear accuracy

5. Non-destructive testing (NDT) for internal and surface quality

6. Optional honing or SRB for mirror-like ID finish

Typical Steel Grades Explained

·ST52 – Excellent toughness, weldability, and machinability

·27SiMn – High strength, good impact resistance, often used in heavy-duty cylinders

·20MnV6 – Micro-alloyed steel with added vanadium for strength and wear resistance

Common Sizes (Stock & Production)

·Ø50 x 5 mm

·Ø63.5 x 7.1 mm

·Ø80 x 8 mm

·Ø100 x 10 mm

·Ø125 x 12.5 mm

·Ø160 x 15 mm

·Ø200 x 20 mm

(Custom dimensions available upon request)

Applications

Hydraulic cylinders for:

·Construction machinery (excavators, loaders, cranes)

·Agricultural equipment (tractors, harvesters, forestry machines)

·Mining machinery (drilling rigs, haulage systems)

·Industrial hydraulic presses

·Heavy lifting and material handling systems

Advantages

·High pressure resistance

·Long service life in tough environments

·Excellent machinability for cylinder manufacturing

·Superior straightness for piston travel

·Compatible with honing & SRB finishing processes

English

English Español

Español русский

русский