Overview

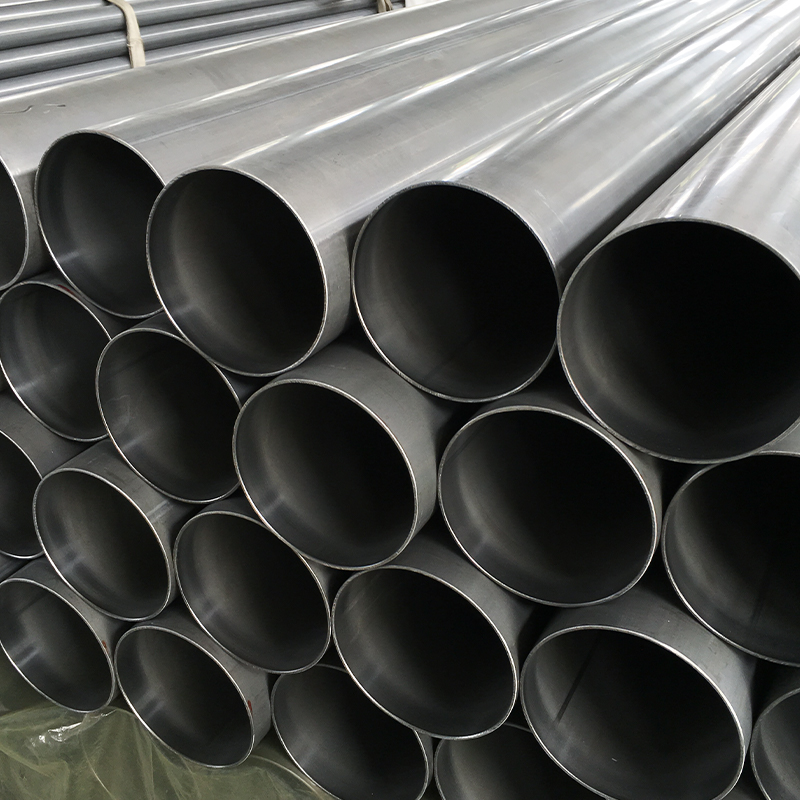

Discover our Cold-Rolled Steel Precision Tubes, engineered to EN 10305-3 standards in grades E235, E355, E195, E275, and E420. Available in sizes from 10 mm to 299 mm outer diameter (OD) and 0.5 mm to 8 mm wall thickness (WT), including the popular Ø25 mm OD x 1.5 mm WT, these tubes offer exceptional dimensional accuracy, smooth surface finish, and reliable mechanical properties. Ideal for mechanical fabrication, including hydraulic cylinders, conveyor rollers, and automotive components, our tubes deliver precision and durability across industries.

Manufacturing Process

Our EN 10305-3 precision tubes are produced through a meticulous cold-rolling process, ensuring high quality and precision:

1. Hot Rolling: Steel strips are hot-rolled and welded to form a continuous tube, providing a strong base material.

2. Cold Rolling: Tubes are cold-rolled to achieve precise dimensions (e.g., Ø25 mm OD x 1. 5 mm WT), improving surface quality and dimensional accuracy.

3. Heat Treatment: Tubes undergo normalizing or annealing to optimize mechanical properties and ensure uniform microstructure.

4. Surface Finishing: Tubes are finished to achieve a smooth, clean surface, suitable for mechanical fabrication and aesthetic applications.

5. Quality Testing: Rigorous inspections, including dimensional checks, tensile testing, and surface quality assessments, ensure compliance with EN 10305-3 standards.

This process delivers tubes with tight tolerances, enhanced strength, and a superior surface finish, ideal for precision mechanical applications.

Material Grades

Our precision tubes are available in grades E235, E355, E195, E275, and E420, each tailored for specific applications and available in various delivery conditions:

Chemical Composition Comparison (Max % unless specified)

|

Grade

|

Carbon (C)

|

Silicon (Si)

|

Manganese (Mn)

|

Phosphorus (P)

|

Sulfur (S)

|

|

E235

|

0.17

|

0.35

|

1. 20

|

0.025

|

0.025

|

|

E355

|

0.22

|

0.55

|

1. 60

|

0.025

|

0.025

|

|

E195

|

0.15

|

0.35

|

0.70

|

0.025

|

0.025

|

|

E275

|

0.21

|

0.35

|

1. 40

|

0.025

|

0.025

|

|

E420

|

0.16

|

0.50

|

1. 70

|

0.025

|

0.020

|

Note: E420 may include trace elements (e.g., Nb ≤0.07%, V ≤0.10%) for enhanced strength, but these are excluded for brevity.

Mechanical Properties Comparison (Normalized, +N)

|

Grade

|

Tensile Strength (N/mm²)

|

Yield Strength (N/mm², min)

|

Elongation (%, min)

|

|

E235

|

340–480

|

235

|

25

|

|

E355

|

490–630

|

355

|

22

|

|

E195

|

320–440

|

195

|

28

|

|

E275

|

400–540

|

275

|

23

|

|

E420

|

520–670

|

420

|

19

|

Note: Mechanical properties are for the normalized (+N) condition. Properties may vary in other delivery conditions (e.g., cold-finished or annealed), with differences in strength, hardness, or formability.

Delivery Conditions

· Normalized (+N): Tubes are heat-treated at a controlled temperature and cooled in air to ensure uniform mechanical properties, ideal for mechanical fabrication requiring consistent strength and formability (e.g., cylinders and rollers).

· Cold-Finished/Soft (+CR1): Tubes are cold-rolled without subsequent heat treatment, offering higher hardness and tighter tolerances for precision components like conveyor rollers.

· Cold-Finished/Hard (+CR2): Tubes are cold-rolled to maximize strength and dimensional accuracy, suitable for high-stress applications like hydraulic cylinders.

· Stress-Relieved (+SR): Tubes are heat-treated after cold-rolling to relieve internal stresses, improving ductility for applications requiring bending or forming.

· Annealed (+A): Tubes are annealed to enhance formability and reduce hardness, ideal for complex fabrication processes like tube bending for structural components.

Grade Descriptions

· E235 (EN 10305-3): A non-alloy carbon steel with moderate strength and excellent weldability, ideal for general mechanical fabrication, such as hydraulic cylinders and conveyor rollers in standard environments.

· E355 (EN 10305-3): A higher-strength non-alloy carbon steel, offering improved mechanical properties for demanding applications like heavy-duty hydraulic cylinders or high-load conveyor rollers.

· E195 (EN 10305-3): A low-carbon, high-formability steel, perfect for applications requiring extensive forming or bending, such as lightweight conveyor rollers or structural tubing in furniture.

· E275 (EN 10305-3): A non-alloy steel with balanced strength and formability, suitable for medium-duty applications like conveyor rollers or structural components in machinery.

· E420 (EN 10305-3): A high-strength steel with enhanced yield strength, ideal for heavy-duty applications like high-pressure hydraulic cylinders or robust conveyor systems.

Specifications

· Standard: EN 10305-3 (Welded Cold Sized Steel Tubes for Precision Applications)

· Size Range:

1. Outer Diameter (OD): 10 mm to 299 mm (e.g., Ø25 mm OD as a common size)

2. Wall Thickness (WT): 0.5 mm to 8 mm (e.g., 1. 5 mm WT as a common size)

3. Length: Random (1,000–12,000 mm) or custom-cut

· Tolerances (per EN 10305-3):

1. OD (10–30 mm): ±0.08 mm; (31–50 mm): ±0.15 mm; (>50 mm): ±0.5%

2. WT: ±10% or ±0.12 mm (whichever is greater)

3. Length: ±3 mm (for cut lengths)

· Delivery Conditions:

1. Normalized (+N): For consistent mechanical properties.

2. Cold-Finished/Soft (+CR1): For high precision and moderate strength.

3. Cold-Finished/Hard (+CR2): For maximum strength and accuracy.

4. Stress-Relieved (+SR): For improved ductility.

5. Annealed (+A): For enhanced formability.

· Surface Conditions: Smooth, clean, or coated (e.g., oiled or phosphated) for corrosion resistance and fabrication ease.

Key Benefits

1. High Precision: Cold-rolled process ensures tight tolerances (e.g., Ø25 mm OD ±0.08 mm, 1. 5 mm WT ±10%) for precise mechanical components.

2. Smooth Surface Finish: Clean, uniform surface reduces friction in conveyor rollers and enhances cylinder performance.

3.Excellent Weldability: Low carbon content in E235, E355, E195, E275, and E420 ensures reliable welds for cylinder and roller assemblies.

4.Versatile Size Range: Sizes from 10 mm to 299 mm OD and 0.5 mm to 8 mm WT suit small to heavy-duty applications.

5.Flexible Delivery Conditions: Normalized, cold-finished, or annealed options meet diverse fabrication needs.

6.Cost-Effective: Non-alloy steels provide reliable performance at a lower cost compared to alloyed or stainless steels.

Applications

EN 10305-3 E235, E355, E195, E275, and E420 precision tubes (e.g., Ø25 mm OD x 1. 5 mm WT) are used in:

· Hydraulic and Pneumatic Cylinders: Barrels for pistons in automation systems, agricultural machinery, or industrial equipment. E355 and E420 (+CR2 condition) are ideal for high-pressure cylinders, while E235, E195, and E275 (+N or +SR) suit standard applications.

· Conveyor Rollers: Outer shells for rollers in manufacturing, logistics, or material handling systems. E195’s high formability (+A condition) is perfect for lightweight rollers, while E235, E275, and E355 (+CR1) ensure durability in heavier systems.

· Mechanical Fabrication: Precision components like shafts, spacers, and structural supports in machinery.

· Automotive: Suspension components, steering systems, and exhaust supports (E235, E355, or E420, +N condition).

· Furniture and Design: Tubular frames for industrial or aesthetic applications (E195 or E275, +A condition for formability).

· General Engineering: Telescopic systems, rollers, and precision fittings.

Quality Assurance

· All E235, E355, E195, E275, and E420 precision tubes comply with EN 10305-3 standards.

·Test certificates per DIN EN 10204 3.1 are provided, verifying chemical composition, mechanical properties, and dimensional accuracy.

· Additional tests, such as eddy current testing, flattening tests, and surface inspections, ensure reliability and performance.

Why Choose Our Precision Tubes?

· Tailored Solutions: Custom sizes (10 mm to 299 mm OD, 0.5 mm to 8 mm WT) and delivery conditions (normalized, cold-finished, stress-relieved, annealed) to meet your project needs.

· Global Standards Compliance: Manufactured to EN 10305-3 for consistent quality.

· Reliable Supply Chain: Stocked in standard sizes (e.g., Ø25 mm OD x 1. 5 mm WT) and customizable for specific applications.

· Expert Support: Our team provides technical guidance to select the ideal grade, size, and delivery condition for cylinders, rollers, or other mechanical fabrication needs.

For more information or to request a quote, contact us at hongli-jy@126.com or visit hltube.com. Elevate your projects with high-quality EN 10305-3 E235, E355, E195, E275, and E420 Cold-Rolled Steel Precision Tubes.

English

English Español

Español русский

русский