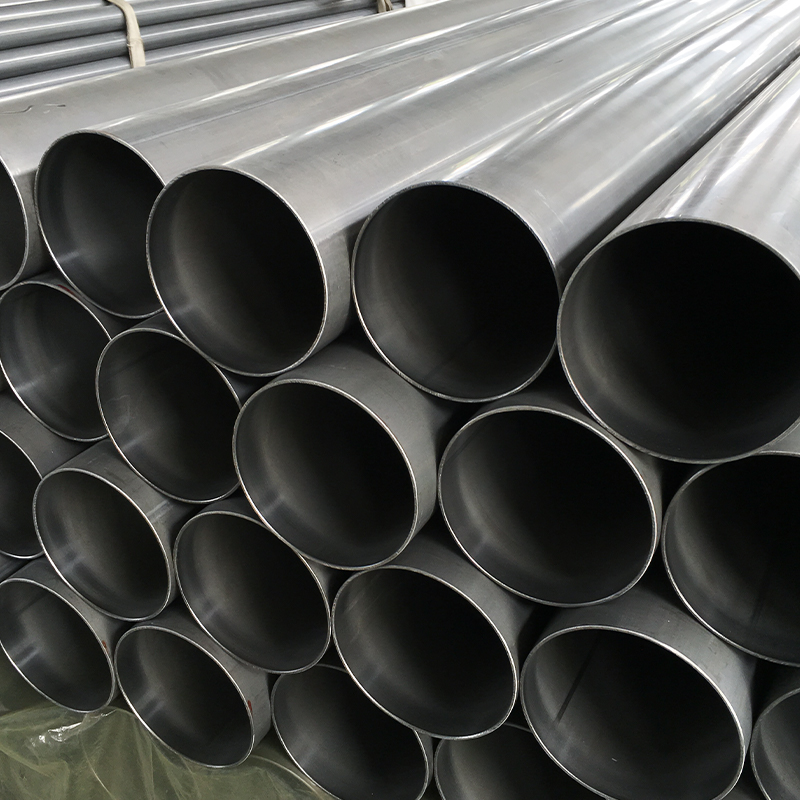

Precision Cold Drawn Welded Steel Tubes (CDW) – EN 10305-2 E235 & E355

High-Tolerance Steel Tubing for Hydraulic, Automotive & Mechanical Engineering

Suao Metal manufactures cold drawn welded (CDW) steel tubes to strict EN 10305-2 standards in grades E235 and E355. Our precision-drawn tubes offer exceptional dimensional accuracy, superior surface quality, and enhanced mechanical properties – perfect for critical applications where reliability matters.

Key Advantages of Our EN 10305-2 CDW Tubes

·Ultra-Precise Dimensions – Tight tolerances (DIN EN ISO 3304) for exact fitment

·Enhanced Strength – Cold working increases yield strength by 15-20% vs. hot-finished

·Premium Surface Quality – Smooth, scale-free finish (Ra ≤ 2.5μm) ready for plating/painting

·Strict Standard Compliance – Full traceability to EN 10305-2 specifications

·Material Versatility – Available in both E235 (S235JR equivalent) and higher-strength E355 (S355JR equivalent)

Technical Specifications

|

Parameter

|

E235

|

E355

|

|

Yield Strength (MPa)

|

≥235

|

≥355

|

|

Tensile Strength (MPa)

|

340-470

|

490-630

|

|

Elongation (%)

|

≥25

|

≥22

|

|

Impact Test Temp

|

+20°C

|

-20°C

|

|

Common Applications

|

Hydraulic cylinders, furniture

|

Automotive chassis, load-bearing parts

|

Complete Size Range (Stock & Custom)

|

Outer Diameter (OD)

|

Wall Thickness

|

Standard Length

|

Tolerance

|

MoQ

|

|

6mm - 30mm

|

0.5mm - 3.0mm

|

1m - 12m

|

±0.03mm

|

500kg

|

|

32mm - 60mm

|

1.0mm - 5.0mm

|

1m - 12m

|

±0.04mm

|

1000kg

|

|

65mm - 120mm

|

1.5mm - 8.0mm

|

1m - 12m

|

±0.5mm

|

2000kg

|

|

121mm - 180mm

|

2.0mm - 12.0mm

|

1m - 12m

|

±0.10mm

|

3000kg

|

|

182mm - 299mm

|

3.0mm - 20.0mm

|

1m - 12m

|

±0.15mm

|

3000kg

|

Notes:

·All sizes available in E235 (S235JR) and E355 (S355JR)

·Custom lengths up to 12 meters

·Special tolerances (±0.03mm) for precision applications

·MOQ flexible for trial orders

Advanced Production Process

·HF-ERW Welding

·First Cold Drawing

·Heat Treatment

·Final Cold Drawing

·Straightening

·Eddy Current Testing

·Laser Measurement

·Packaging

Key Advantages:

·HRC Steel Coils

·Dual Cold Drawing: Enhances dimensional accuracy beyond EN 10305-2 requirements

·In-Line Testing: 100% eddy current + 10% hydrostatic pressure testing

·Surface Control: Ra ≤ 2.0μm achievable for critical applications

Material Comparison

|

Property

|

E235

|

E355

|

Best For

|

|

Yield Strength

|

235MPa

|

355MPa

|

Structural vs High-Load

|

|

Elongation

|

25%

|

22%

|

Forming vs Rigidity

|

|

Impact Test

|

+20°C

|

-20°C

|

Indoor vs Outdoor

|

|

Weldability

|

Excellent

|

Good

|

General vs Specialized

|

Why Engineers Choose Us

·Mega-Stock: 5,000+ metric tons across all sizes

·Just-in-Time Processing: Cut-to-length within 24 hours

·Certified Quality: EN 10204 3.1/3.2 certifications available

·Global Logistics: FOB/CIF terms to 150+ countries

Global Standard Equivalents

|

EN 10305-2

|

DIN

|

ASTM

|

ISO

|

|

E235

|

ST37.2

|

A513 Type 5

|

C22E

|

|

E355

|

ST52.3

|

A519 Grade 1026

|

C35E

|

Typical Applications

·Hydraulic Systems (Cylinder tubes, piston rods)

·Automotive Components (Steering columns, drive shafts)

·Mechanical Engineering (Linear motion systems, bearing sleeves)

·Industrial Machinery (Textile equipment, conveyor systems)

Get Your Custom Quote Today:

[Button] Download Full Technical Dossier

[Button] Request Instant Pricing

English

English Español

Español русский

русский