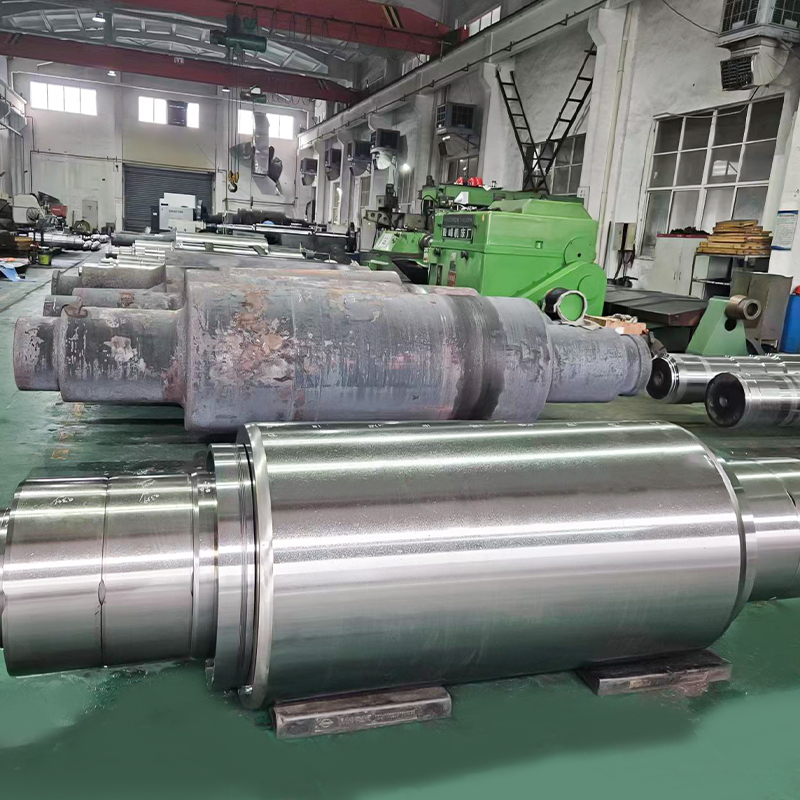

Our high-quality cast steel bearing housings are designed for extreme loads and precision performance in demanding industrial applications. Made from ASTM A216 WCB cast steel and optionally other premium grades, these housings ensure high durability, reliability, and accuracy.Available in bore sizes from Ø50 mm to Ø1500 mm (1.969–59.055 in), outer diameters from 100 mm to 2000 mm, and widths from 50 mm to 500 mm, including the heavy-duty standard Ø500 mm bore × 700 mm OD × 200 mm width (19.685 × 27.559 × 7.874 in). Ideal for mining, wind turbines, pumps, conveyors, and large-scale industrial machinery.

Key Features

·Heavy-Duty Strength: ASTM A216 WCB (yield ~250 N/mm²) supports extreme loads.

·Precision Machining: Bore tolerances ±0.05 mm ensure perfect bearing fit.

·Corrosion Resistance: Optional painting, galvanizing, or oil coating.

·Large Size Range: Bore sizes up to Ø1500 mm (59.055 in) for massive bearings.

·Durable Design: Cast steel construction for long-term reliability.

·Customizable Options: Tailored dimensions and finishes for specific applications.

Common Steel Grades

|

Steel Grade

|

Type

|

Yield Strength (N/mm²)

|

Tensile Strength (N/mm²)

|

Elongation (%)

|

Key Applications

|

Notes

|

|

ASTM A216 WCB

|

Cast Carbon Steel

|

~250

|

485–655

|

22

|

Standard & heavy-duty industrial machinery, mining, wind turbines

|

Most widely used; excellent machinability

|

|

ASTM A487 4Q

|

High-Strength Cast Steel

|

~485

|

655–895

|

15–20

|

Extreme-duty applications, large equipment

|

Superior strength for very high loads

|

|

ASTM A217 WC9

|

Cr-Mo Alloy Steel

|

~275

|

485–655

|

18

|

High-temperature applications, turbines, heavy machinery

|

Excellent thermal stability

|

|

AISI 304 (EN 1.4301)

|

Stainless Steel

|

~205

|

515–690

|

40

|

Corrosion-resistant environments, food, marine

|

Ideal for wet or chemically aggressive environments

|

|

ASTM A36

|

Structural Carbon Steel

|

~250

|

400–550

|

20

|

Standard machinery, smaller industrial applications

|

Cost-effective option for lighter loads

|

Typical Sizes & Dimensions

|

Bore Diameter (ID)

|

Outer Diameter (OD)

|

Width

|

Notes

|

|

Ø50 mm

|

120 mm

|

50 mm

|

Small machinery

|

|

Ø200 mm

|

400 mm

|

120 mm

|

Medium machinery

|

|

Ø500 mm

|

700 mm

|

200 mm

|

Heavy-duty industrial

|

|

Ø1000 mm

|

1400 mm

|

350 mm

|

Large equipment

|

|

Ø1500 mm

|

2000 mm

|

500 mm

|

Extreme-duty applications

|

Load Capacity: Up to 50,000 kg (110,231 lb) dynamic, depending on bearing type.

Tolerances: Bore ±0.05 mm for Ø50–500 mm; ±0.1 mm for >500–1500 mm. OD/Width ±0.5 mm for Ø50–500 mm; ±1 mm for >500–1500 mm. Surface finish Ra ≤ 1.6 µm.

Manufacturing Process

1. Casting: Sand or investment casting forms robust housings.

2. Precision Machining: CNC machining achieves bore ±0.05 mm and tight dimensional accuracy.

3. Heat Treatment: Normalized or annealed to enhance strength and toughness.

4. Surface Finishing: Painted, galvanized, or oiled for corrosion resistance.

5. Quality Testing: Dimensional checks, hardness testing, and ultrasonic inspections.

Applications

·Mining: Conveyor systems, crushers, and material handling (WCB, A487 4Q).

·Wind Turbines: Main shaft and gearbox housings (WCB, WC9).

·Heavy Machinery: Pumps, turbines, and industrial equipment (WCB, Ø500 mm bore).

·Corrosive Environments: Food processing or marine applications (AISI 304).

·Standard Applications: Smaller machinery and automotive (A36).

·Secondary Applications: Structural mounts in large equipment, corrosion-resistant fittings, and other custom uses.

Advantages

·Enhanced bearing life with precision fit.

·Reduced vibration and mechanical noise.

·High load-bearing capacity and impact resistance.

·Options for corrosion resistance in harsh environments.

Delivery & Quality Assurance

·Delivery Conditions: Normalized or annealed.

·Surface Conditions: Painted, galvanized, or oiled.

·Compliance: ASTM A216, A487, A217, A36, and AISI standards.

·Certificates: DIN EN 10204 3.1 for chemical composition, mechanical properties, and dimensional accuracy.

English

English Español

Español русский

русский