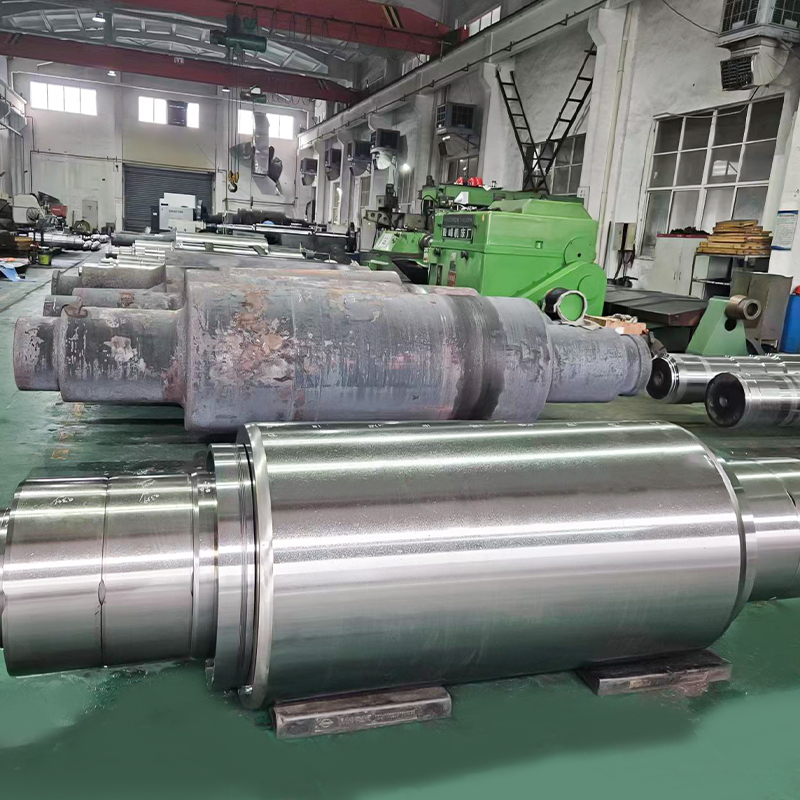

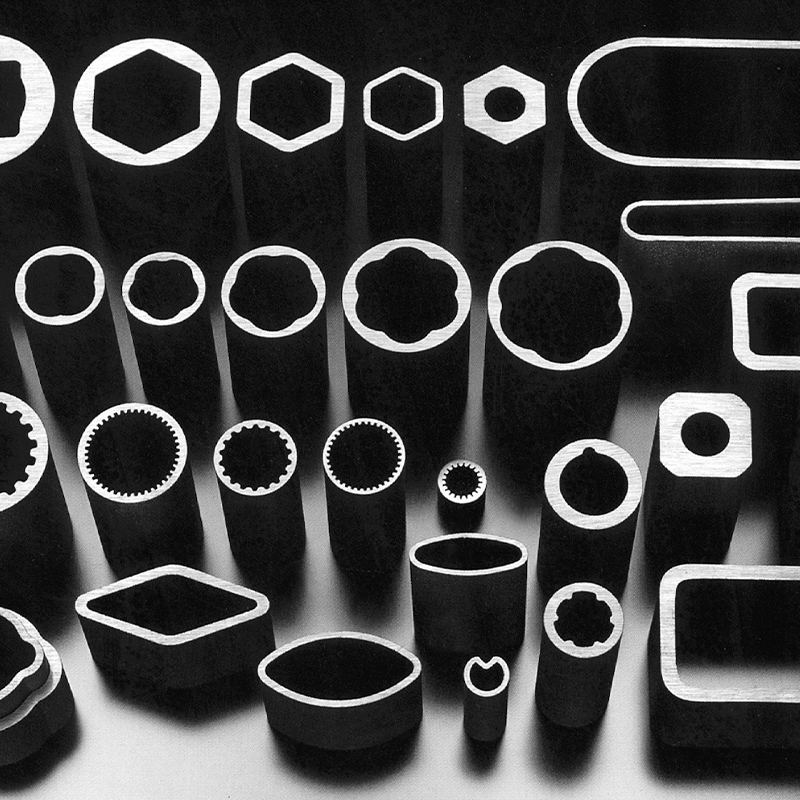

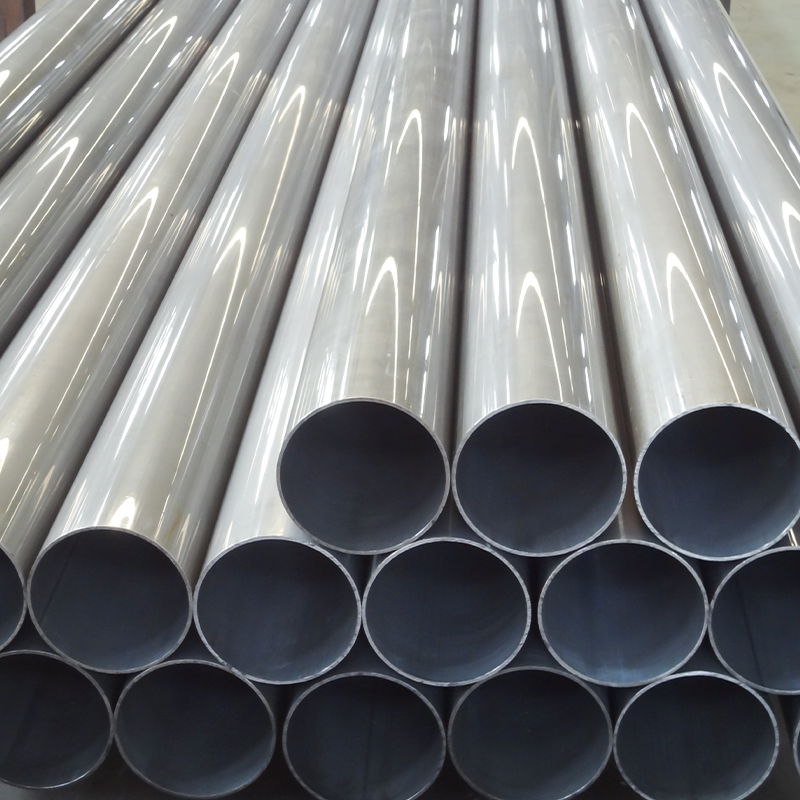

Our Machined Steel Structural Assemblies are precision-engineered for steel and aluminum rolling mill equipment. Designed for maximum strength, stability, and durability, these welded and CNC-finished assemblies support rolling mill frames, bearing mounts, guide rails, and auxiliary components. Available in standard and custom sizes, these assemblies are optimized for load-bearing performance while ensuring corrosion resistance and long service life.

Why Choose Our Machined Steel Structural Assemblies?

·High-Strength Construction: Built with ASTM A36, A572 Gr. 50, AISI 4140, and stainless steel (304/316) to handle extreme loads.

·Precision CNC Finishing: Ensures accurate alignment, tight tolerances, and smooth operation.

·Custom Sizes: Tailored dimensions to fit your rolling mill layout and equipment requirements.

·Corrosion Resistance: Optional finishes include powder coating, galvanization, or polished stainless steel.

·Durable Welded Frames: High-quality welding ensures structural integrity under heavy-duty conditions.

Optional Steel Grades & Typical Dimensions

|

Component

|

Steel Grade Options

|

Typical Dimensions (L × W × H mm)

|

Surface Finish

|

Load Capacity

|

Notes

|

|

Base Frame

|

ASTM A36 / A572 Gr. 50

|

1200 × 1000 × 500

|

CNC-finished, welded

|

1000–1500 kg

|

Standard mill support

|

|

Roll Support Frame

|

ASTM A36 / A572 Gr. 50 / AISI 4140

|

800 × 600 × 400

|

CNC-finished, powder-coated

|

1500–2500 kg

|

Heavy-duty roll support

|

|

Bearing Housing Mount

|

AISI 4140 / ASTM A36 / A572 Gr. 50

|

Ø500 × 700 × 200

|

CNC-finished, welded

|

5000–10000 kg

|

Extreme load-bearing

|

|

Guide Rail Frame

|

ASTM A36 / A572 Gr. 50

|

1000 × 300 × 250

|

CNC-finished

|

500–1000 kg

|

Supports guide rails

|

|

Upper Frame Assembly

|

A572 Gr. 50 / ASTM A36

|

1500 × 1200 × 600

|

CNC-finished, powder-coated

|

2000–3000 kg

|

Multi-roll support

|

|

Corrosion-Resistant Frame

|

AISI 304 / 316

|

1000 × 800 × 500

|

CNC-finished, polished

|

1000–1500 kg

|

Chemical/marine environments

|

|

Auxiliary Support

|

ASTM A36

|

600 × 400 × 300

|

Welded, painted

|

500–800 kg

|

Smaller equipment support

|

Applications

Our Machined Steel Structural Assemblies are ideal for:

·Steel Rolling Mills: Heavy-duty frame supports and precision alignment structures.

·Aluminum Rolling Mills: Lightweight yet strong structural assemblies.

·Industrial Machinery: Custom welded and machined assemblies for conveyors, presses, and rollers.

·High-Load Applications: Areas requiring exact tolerances, vibration resistance, and durability.

·Heavy Industry: Industrial machinery frames, structural support assemblies.

·Corrosive or High-Humidity Environments: Stainless steel options for chemical, marine, or food processing applications.

Manufacturing Process

1. Material Preparation: High-quality steel plates or alloy billets are cut to precise dimensions.

2. Cutting & Forming: Steel plates and sections are cut and formed to exact dimensions.

3. Welding: MIG or TIG welding forms strong, seamless joints for heavy-duty frames.

4. CNC Machining: Precision milling and finishing ensure exact tolerances for all components.

5. Surface Finishing: Powder coating, galvanization, painting, or polishing for corrosion protection.

6. Quality Testing: Load tests, dimensional verification, and weld inspections confirm compliance with industrial standards.

Specifications

·Grades: ASTM A36, A572 Gr. 50, AISI 4140, AISI 304/316

·Dimensions: Customizable; typical ranges in table above

·Surface Conditions: Welded, CNC-finished, powder-coated, galvanized, or polished

·Load Capacity: Up to 10,000 kg for bearing mounts; standard frames 500–3000 kg

Quality Assurance

All assemblies comply with ASTM A36, A572, AISI 4140, and EN standards where applicable. Certificates of conformity per DIN EN 10204 3.1 verify material properties, dimensions, and load capacity. Non-destructive testing (NDT) and weld inspections ensure long-term reliability.

English

English Español

Español русский

русский