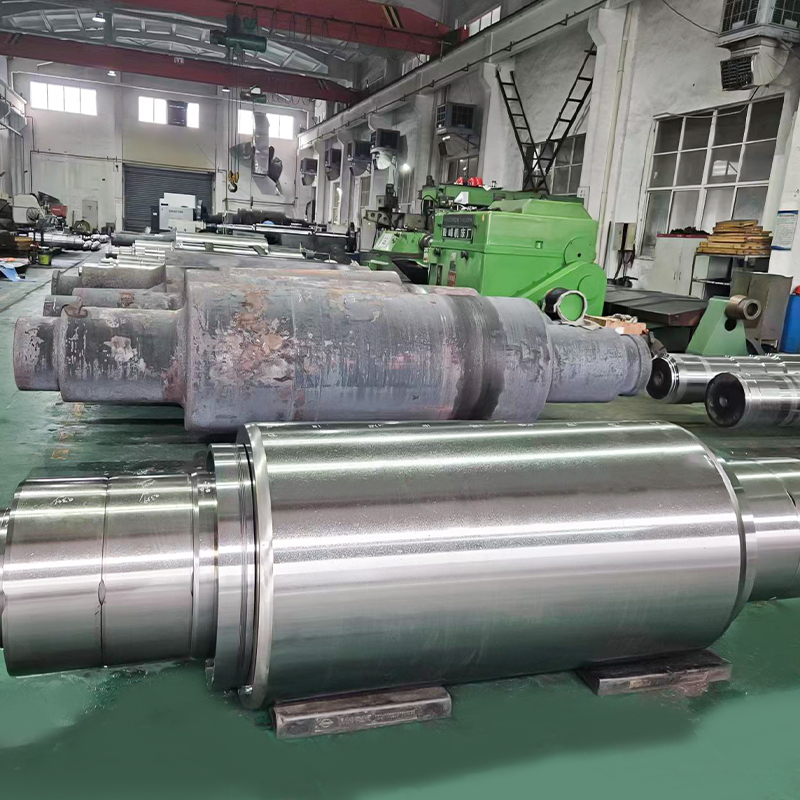

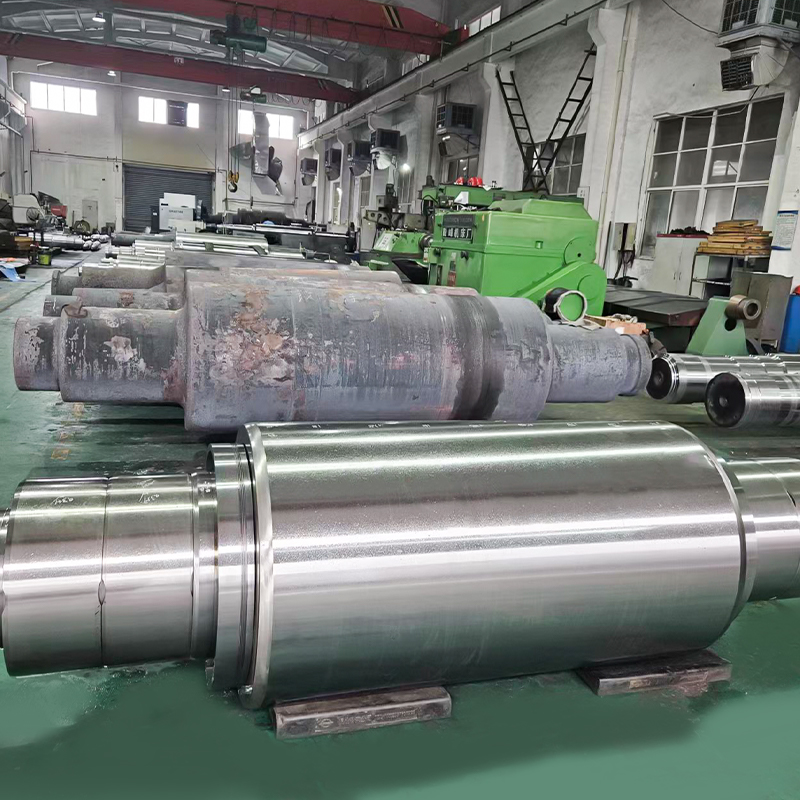

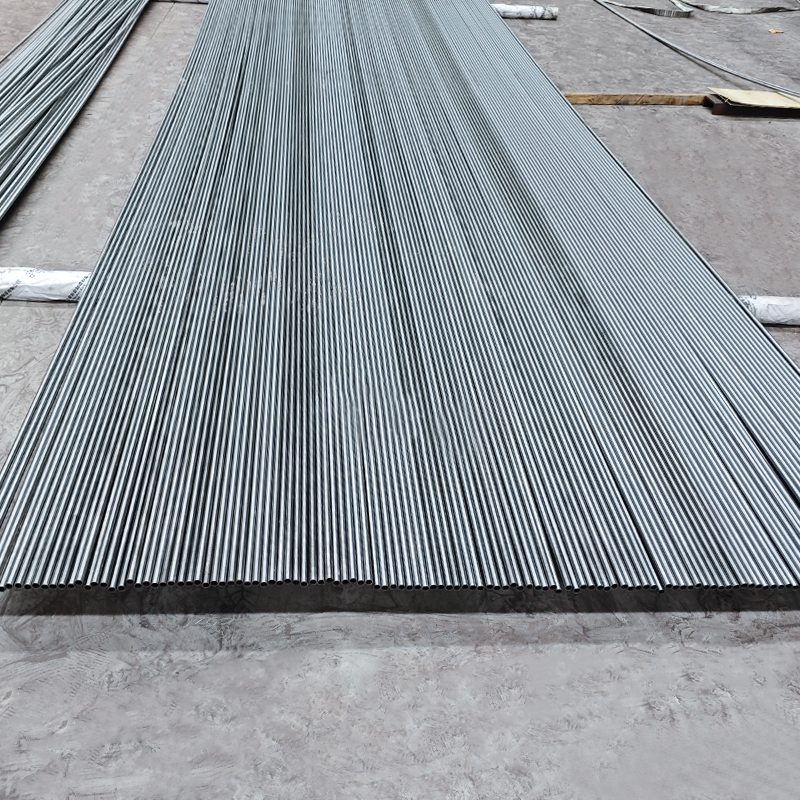

Our forged and machined work rolls are engineered for high-performance rolling mills, combining durability, precision, and heat resistance. Made from high-quality alloy steels like ASTM A681 D2, AISI L6, A2, and other high-alloy grades, these rolls are heat-treated and precision ground for consistent hardness, wear resistance, and optimal rolling quality.Available in custom diameters, lengths, and hardness ranges, these rolls are suitable for hot rolling, cold rolling, and non-ferrous metal production, including steel, aluminum, and copper.Example standard size: Ø500 mm × 2000 mm (19.685 in × 78.74 in)

Key Features

·Superior Hardness: Heat-treated to 58–64 HRC for excellent wear resistance and long service life.

·Precision Ground: Tight tolerances (e.g., Ø500 mm ±0.05 mm, length ±1 mm) for smooth operation and consistent sheet quality.

·Alloy Steel Durability: D2, 86CrMoV7, L6, and A2 steels provide high edge retention and fatigue resistance.

·High-Temperature Resistance: Suitable for hot rolling mills up to ~600°C (1112°F).

·Custom Sizes: Diameters from Ø200–1500 mm and lengths 1000–6000 mm tailored to mill requirements.

·Cost-Effective Performance: Forged construction reduces downtime and maintenance costs.

Typical Steel Grades and Hardness

|

Steel Grade

|

Typical Hardness (HRC)

|

Core Hardness (HRC)

|

Key Properties

|

Typical Applications

|

|

ASTM A681 D2

|

58–64

|

32–36

|

High-carbon, high-chromium tool steel for wear resistance

|

Cold rolling of steel and aluminum sheets

|

|

AISI L6

|

56–62

|

30–34

|

Oil-hardening tool steel with high toughness

|

Non-ferrous and in-house machined rolls

|

|

AISI A2

|

58–62

|

28–32

|

Air-hardening tool steel, precision cold work

|

Cold rolling and finishing rolls

|

|

9Cr2Mo

|

55–60

|

30–32

|

Cr-Mo alloy steel for hot rolling billets

|

Hot rolling applications

|

|

5CrMnMo

|

54–60

|

28–32

|

Cr-Mn-Mo alloy steel for rough rolling

|

Heavy-duty roughing mills

|

|

86CrMoV7

|

58–64

|

32–36

|

High-alloy tool steel for cold rolling

|

High-precision cold rolling

|

Note: Grades like 1Cr9Mo are not typically used for work rolls and are excluded.

Typical Sizes & Dimensions

|

Diameter (OD, mm)

|

Length (mm)

|

Hardness (HRC)

|

Notes

|

|

200

|

1000

|

58–62

|

Small-scale rolling mills

|

|

300

|

1500

|

58–62

|

Medium mills

|

|

500

|

2000

|

58–64

|

Standard hot/cold rolling mills

|

|

700

|

3000

|

60–64

|

Large industrial mills

|

|

1000

|

4000

|

61–64

|

Heavy-duty mills

|

|

1500

|

6000

|

62–64

|

Ultra-large mills

|

|

Custom

|

Custom

|

58–64

|

Tailored to customer requirements

|

Manufacturing Process

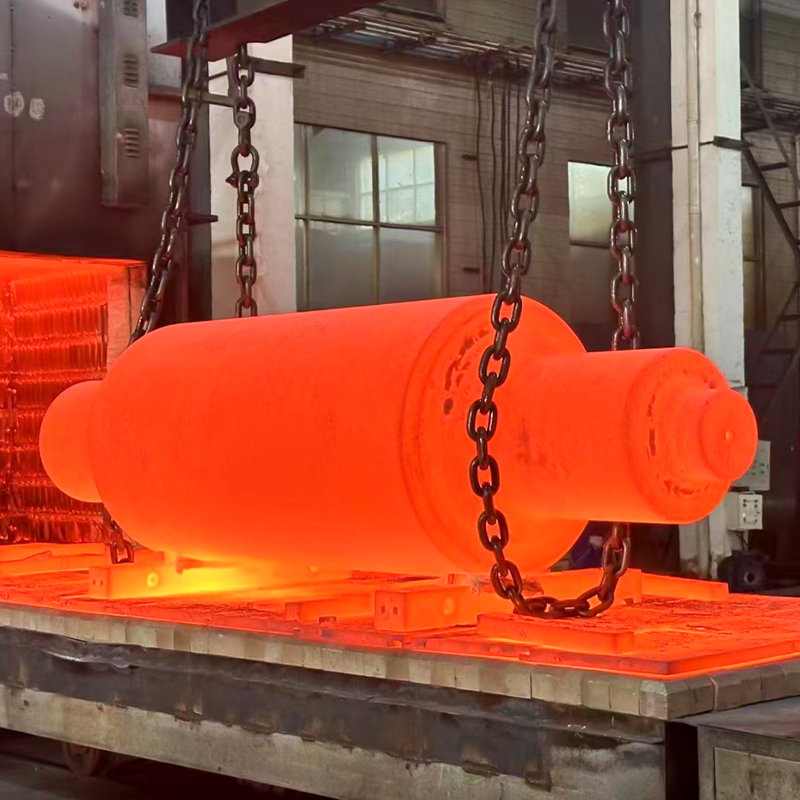

1. Forging: Alloy steel billets are hot-forged to dense, near-net roll shapes.

2. Heat Treatment: Quenching and tempering for hardness of 58–64 HRC, enhancing wear resistance and toughness.

3. Precision Grinding: Cylindrical and journal surfaces ground to Ra ≤ 0.4 µm for smooth rolling.

4. Surface Finishing: Polished or chrome-plated for corrosion and marking resistance.

5. Quality Testing: Dimensional checks, hardness testing, and non-destructive testing (ultrasonic or magnetic particle inspection) ensure compliance with ASTM A681 standards.

Applications

·Rolling Mills: Hot rolling of steel/aluminum, cold rolling of precision strips, non-ferrous metal rolling.

·High-Speed Rolling: Advanced mills requiring uniform surface and minimal vibration.

·Heavy-Duty Industrial Use: Large-scale production lines requiring high-strength rolls.

·Secondary Uses: Limited precision structural components and tooling for manufacturing.

Delivery & Quality Assurance

·Delivery Conditions: Heat-treated, precision ground, ready for installation.

·Surface Conditions: Polished (Ra ≤ 0.4 µm), optional chrome plating.

·Compliance: ASTM A681, AISI, and equivalent international standards.

·Certificates: Material test reports per DIN EN 10204 3.1.

English

English Español

Español русский

русский