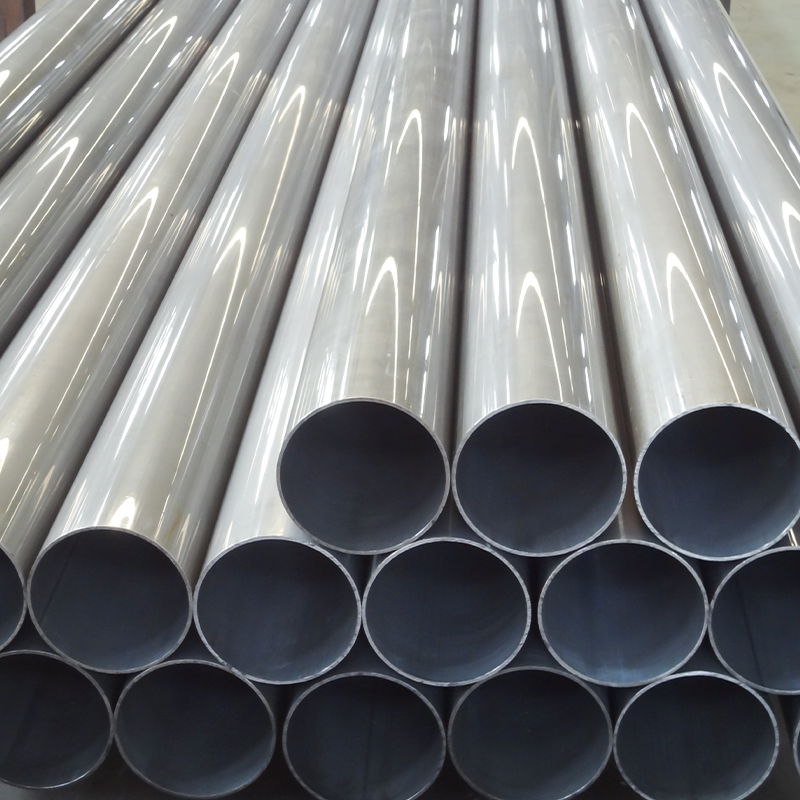

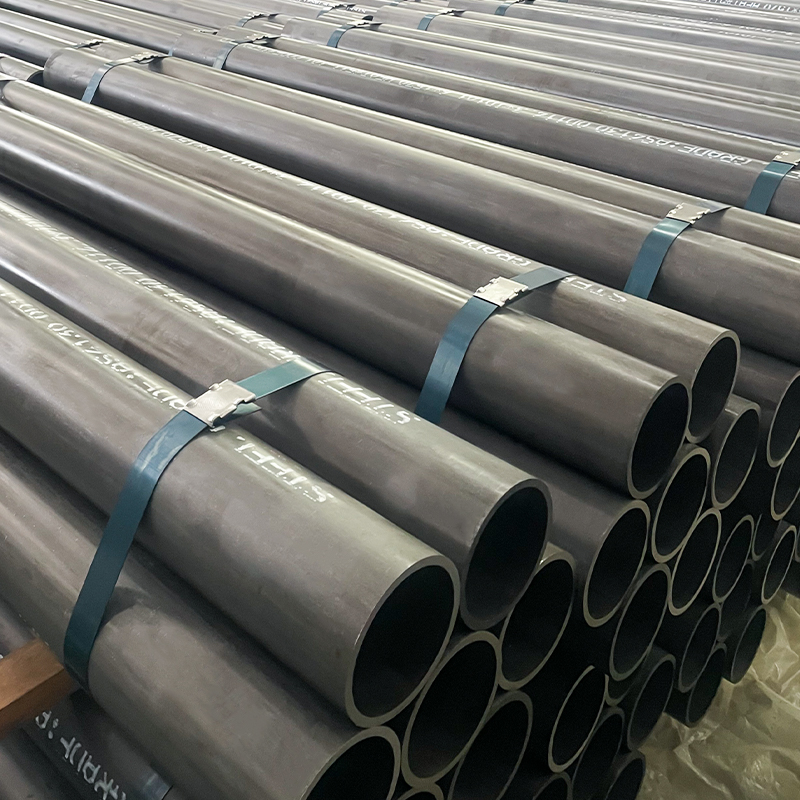

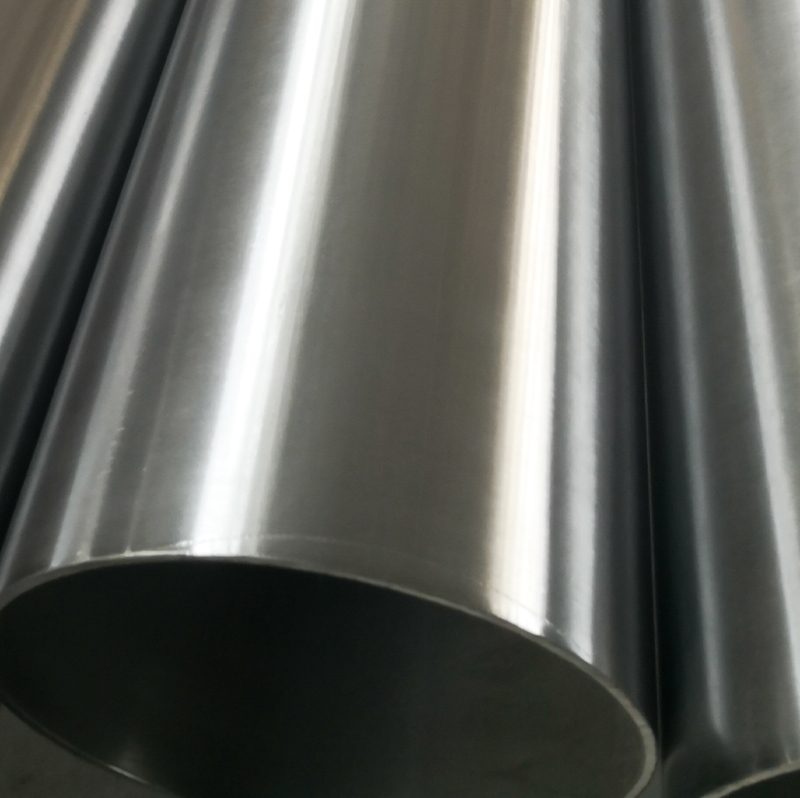

Cold Drawn Welded Steel Tube (CDW) – DIN 2393 | ASTM A513 (ST37-2, ST52-3)

High-Precision CDW Steel Tubes for Hydraulic, Automotive & Industrial Applications

Suao Metal supplies premium Cold Drawn Welded (CDW) Steel Tubes manufactured to DIN 2393a and ASTM A513 standards, available in grades ST37-2 and ST52-3. Our precision-engineered tubes deliver superior strength, tight tolerances, and excellent surface finishes—ideal for demanding industrial applications.

Key Features & Benefits

·Cold Drawn Precision – Enhances mechanical properties (higher tensile strength, improved hardness).

·Strict Compliance – Meets DIN 2393 (Germany) & ASTM A513 (USA) specifications.

·Smooth Surface Finish – Burr-free, ready for machining, coating, or welding.

·Wide Material Range – ST37-2 (S235JR equivalent) for weldability & ST52-3 (S355JR equivalent) for high-load applications.

·Custom Sizes – Available in various OD, wall thicknesses, and lengths to fit your requirements.

Common Applications

·Hydraulic & Pneumatic Systems (Cylinder tubes, actuator components)

·Automotive Parts (Chassis, transmission, fuel lines)

·Machinery & Bearings (Conveyor rollers, bushings, shafts)

·Construction & Structural Engineering (Scaffolding, support frames)

Standards & Equivalent Grades

|

Standard

|

Grade

|

Key Properties

|

Equivalent Grades

|

|

DIN 2393

|

ST37-2

|

Low carbon, good formability

|

S235JR (EN), Q235B (GB)

|

|

DIN 2393

|

ST52-3

|

High strength, load-bearing

|

S355JR (EN), Q355B (GB)

|

|

ASTM A513

|

Type 5 (ERW)

|

Electric-resistance welded

|

AISI 1018, 1026

|

High-Precision CDW Tubes up to 299mm OD – Custom Sizes Available

Complete Size Range

|

Outer Diameter (OD)

|

Wall Thickness

|

Standard Length

|

Tolerance

|

Grades Available

|

|

8mm - 30mm

|

0.8mm - 3.0mm

|

2m - 12m

|

h9 (DIN 2393)

|

ST37-2, ST52-3

|

|

32mm - 60mm

|

1.2mm - 5.0mm

|

2m - 12m

|

h10

|

ST37-2, ST52-3

|

|

63mm - 120mm

|

1.5mm - 8.0mm

|

2m - 12m

|

h11

|

ST37-2, ST52-3

|

|

121mm - 180mm

|

2.0mm - 12.0mm

|

2m - 12m

|

h11

|

ST52-3

|

|

182mm - 299mm

|

3.0mm - 20.0mm

|

2m - 12m

|

h12

|

ST52-3

|

Key Notes:

·All tubes comply with DIN 2393 Part 1/2 and ASTM A513 Type 5

·Special sizes available with OD 300-450mm (MOQ applies)

·Custom lengths up to 12 meters for structural applications

·Surface roughness: Ra ≤ 1.6μm (achievable with secondary processing)

Advanced Production Process

Material Preparation

·Cold-rolled steel strips (DIN EN 10139)

·Chemical composition verified via spectrometer

High-Frequency Welding

·ERW process at 400kHz frequency

·Weld seam annealed for uniform microstructure

Cold Drawing Process

·Multi-stage drawing with tungsten carbide dies

·15-30% cross-section reduction per pass

·Intermediate annealing (650-750°C) between draws

Final Processing

·Rotary straightening (±0.1mm/m straightness)

·Ultrasonic testing (100% coverage)

·Phosphating/oiling for corrosion protection

Technical Comparison: ST37-2 vs ST52-3

|

Property

|

ST37-2 (DIN 2393)

|

ST52-3 (DIN 2393)

|

ASTM A513 Equivalent

|

|

Yield Strength

|

≥235 MPa

|

≥355 MPa

|

Type 5 (1018)

|

|

Tensile Strength

|

340-470 MPa

|

490-630 MPa

|

Type 5 (1026)

|

|

Elongation (A₅)

|

≥23%

|

≥20%

|

-

|

|

Impact Test

|

+20°C

|

-20°C

|

-

|

|

Carbon Content

|

≤0.17%

|

≤0.20%

|

-

|

Typical Applications

·ST37-2: Furniture frames, conveyor rollers, light structural components

·ST52-3: Hydraulic cylinders, truck chassis, crane booms

·Special Uses: Pneumatic systems (ISO 7180), automotive safety parts

Why Choose Our CDW Tubes?

·Dual Certification: Complies with both DIN and ASTM standards

·Mega Inventory: 8,000+ tons in warehouses

Special Services:

1. ID/OD grinding (±0.01mm precision)

2. Zinc plating (up to 20μm coating)

3. Laser cutting for complex geometries

Contact Our Engineering Team:

[Button] Download DIN 2393 Full Spec Sheet

[Button] Get Instant Pricing for Large Quantities

English

English Español

Español русский

русский